Optical inspection of surface finishes

By automating the inspection, the human factor is eliminated as a potential source of error and the quality of the inspection is therefore significantly increased. Inspections are carried out on the basis of a previously defined quality standard, the deviations of which are identified 100 percent. In addition to 3D surface inspection and precise dimensional inspection, our inspection systems also offer you the option of defect classification and precise counting.

In addition to surface inspection and dimensional control, further sensors can be integrated into the system concepts if required.

Our inspection systems check the surfaces of your workpieces on the basis of a defined quality standard. This allows defects to be classified, precise dimensional checks and exact counts to be carried out.

Dimensions:

Slide 10-35 mm, thickness 1 – 3.5 mm

Material:

all coin materials

Features:

Stains, color differences, damage, deformation

Tools:

2D and 3D inspection,

Edge inspection and/or EMS sensor optional

Inspected pages:

2

degree of automation:

high

Speed:

up to 3000 pcs/min at dia. 20 mm

Dimensions:

Slide 10-35 mm, thickness 1 – 3.5 mm

Material:

all coin materials

Features:

Stains, color differences, damage, relief defects, deformation

Tools:

2D and 3D camera technology,

optional 2D camera technology for edge inspection and/or EMS sensor

Inspected pages:

2

degree of automation:

high

Speed:

up to 2000 pcs/min at dia. 20 mm

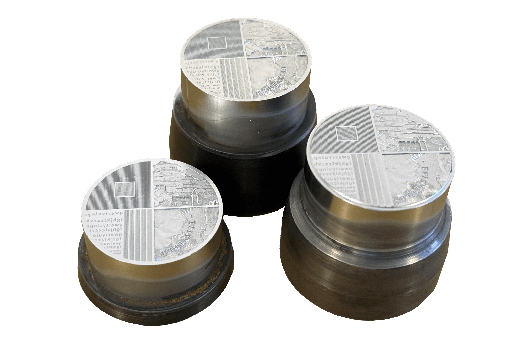

Dimensions:

Slide 20-80 mm, height 30-80 mm

Material:

Tool steel

Features:

Stains, color differences, damage, relief defects

Tools:

2D and 3D camera technology

Inspected pages:

1

degree of automation:

low

Speed:

Manual parts handling

Dimensions:

Slide 8-40 mm, thickness 1 – 4 mm

Material:

Carbon steel

Features:

Outer and inner diameter, contingency, material thickness, inner and outer chamfer, surface defects

Tools:

2D and 3D camera technology

Inspected pages:

2

degree of automation:

high

Speed:

1600 pcs/min

Dimensions:

Length 11.9 – 15.7 mm, width 6.9 – 8.7 mm

Material:

Steel (hardened)

Strength:

1.2 – 2.2 mm

Features:

Length, width, material thickness, surface defects

Tools:

3D camera technology

Inspected pages:

1

degree of automation:

high

Speed:

422,000 pcs./70 min.

Dimensions:

Length 24.4 – 24.75 mm, width 11.7 – 15.7 mm

Material:

Steel (hardened), stainless steel (soft)

Strength:

1.5 – 1.75 mm

Features:

Length, width, material thickness, surface defects, material hardness

Tools:

3D camera technology, eddy current technology

Inspected pages:

1

degree of automation:

high

Speed:

960 pcs./min.

Christian Hollands

Sales

Precision stamped parts and inspection technology

Michael Steenkamp

Project management

Inspection technology

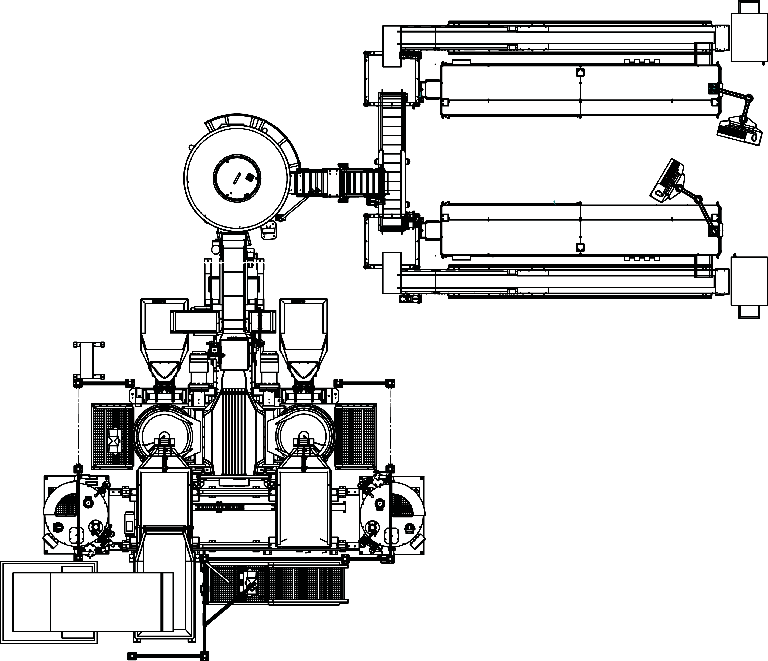

Our proprietary software solution makes it possible to solve the inspection task in a customer-specific manner and includes the option of defect classification and statistical evaluation.

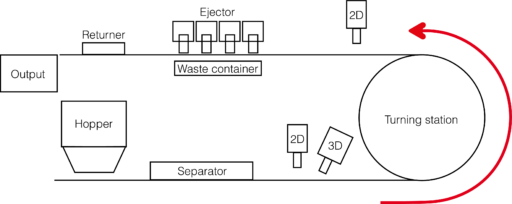

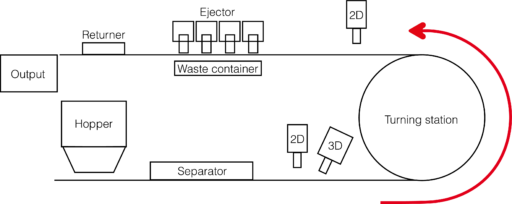

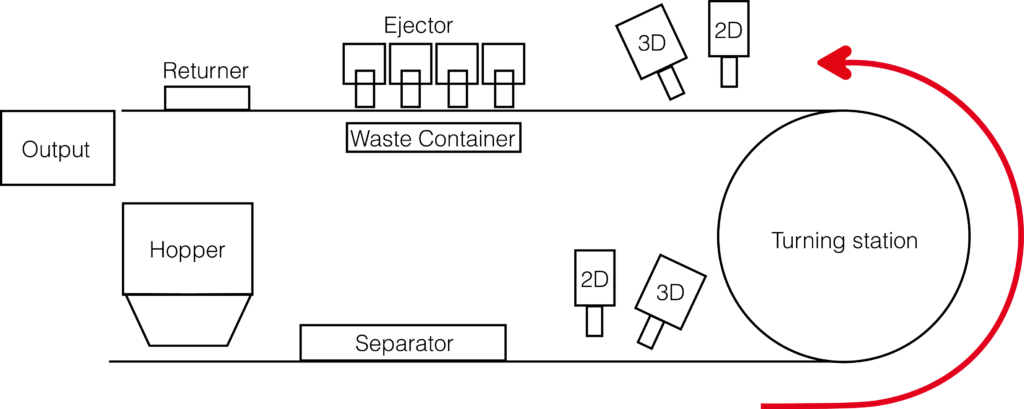

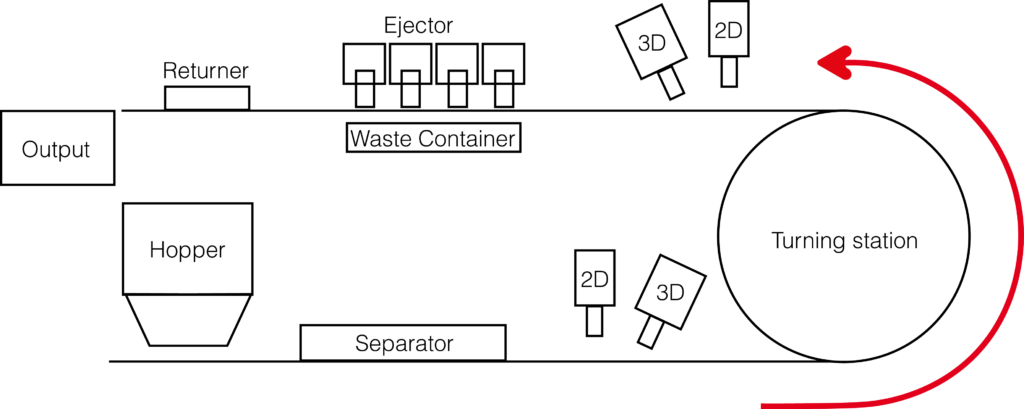

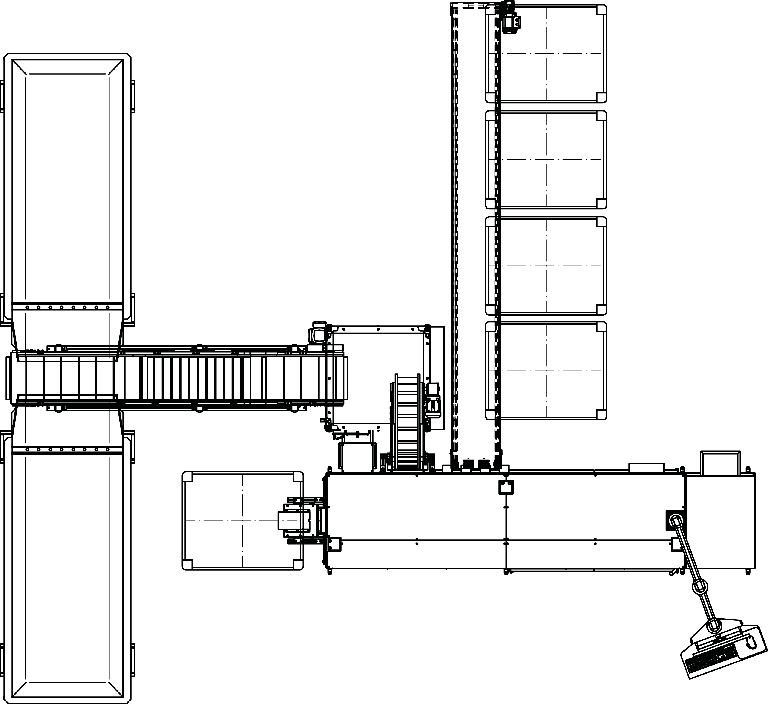

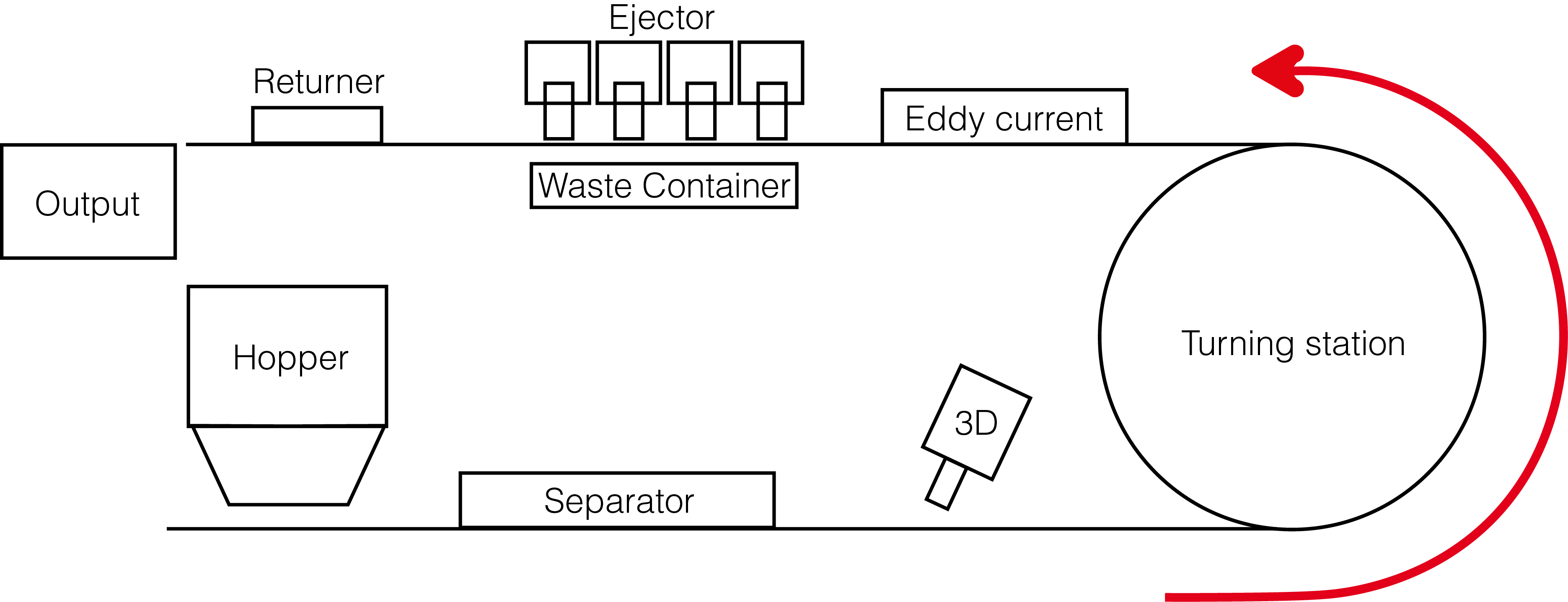

The material handling is realized by our in-house machine construction in coordination with the requirements of the inspection technology.

SPALECK Oberflächentechnik

GmbH & Co. KG

Schlavenhorst 117

D-46395 Bocholt

Inspektion

Für eine optische Inspektion gelten die gleichen Anforderungen wie für das menschliche Auge. Wichtig ist die Beschreibung des Bauteils, die Definition der zu prüfenden Merkmale und die Festlegung der Toleranzen.

Handling

Die Vielfalt der Bauteile und der gewünschte Automatisierungsgrad machen das Bauteilhandling entscheidend. Der Transport und die präzise Positionierung unter dem Inspektionstool sind ausschlaggebend für ein optimales Inspektionsergebnis.

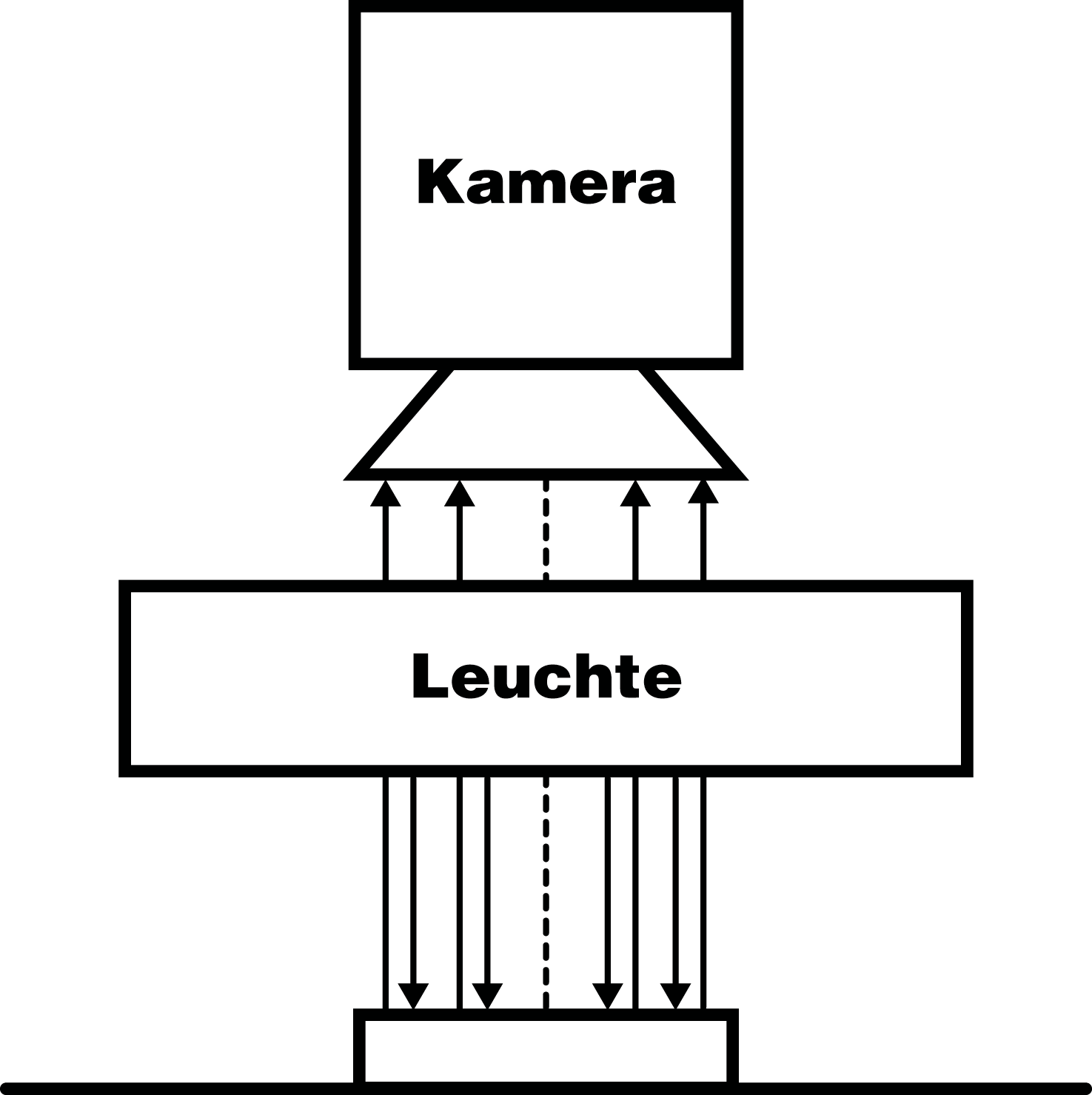

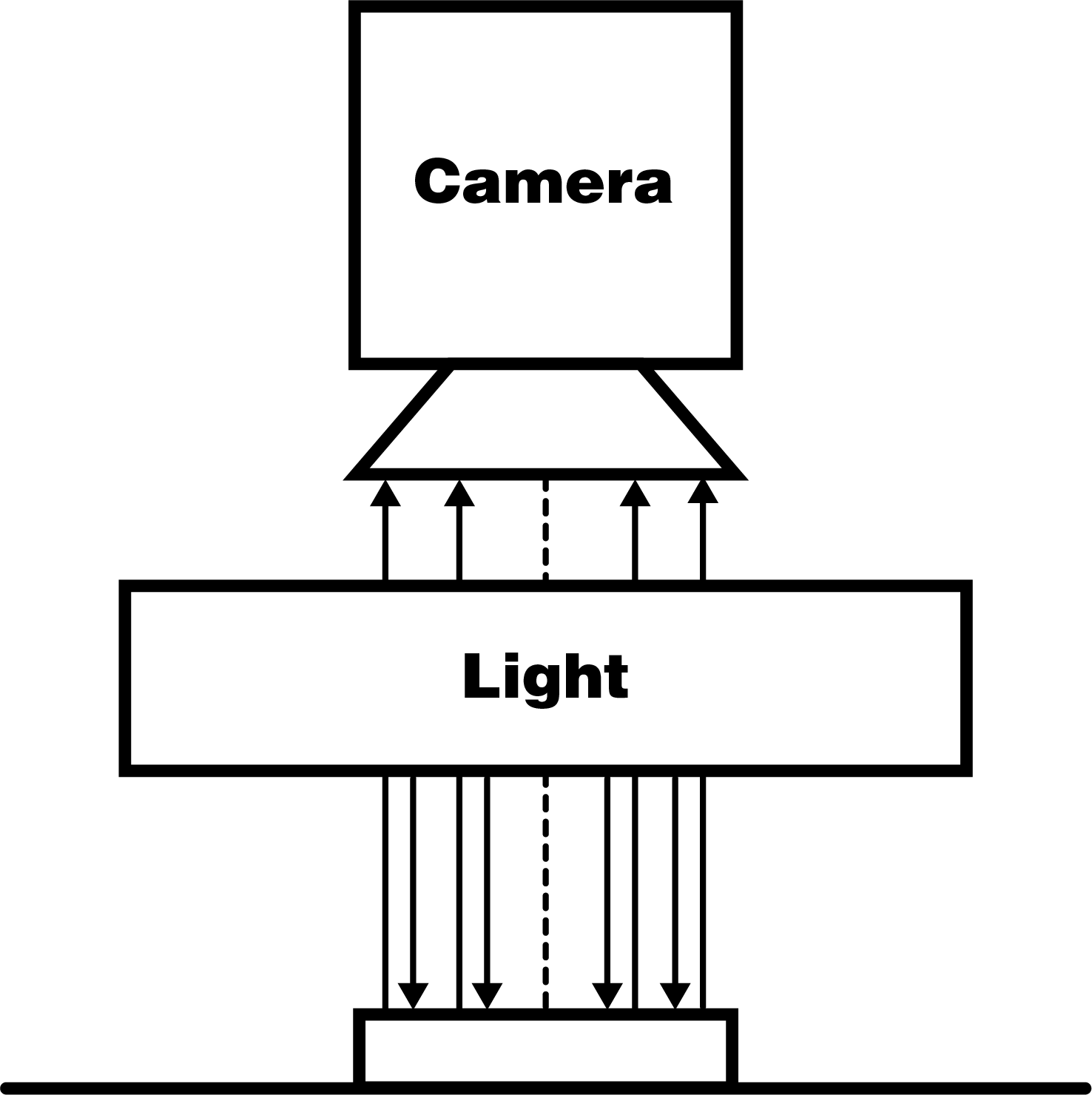

Bildgewinnung

Die Bildgewinnung umfasst die Auswahl der Beleuchtungs- und Kameratechnik. Dabei werden Art und Empfindlichkeit der Komponenten entsprechend den zuvor definierten Prüfmerkmalen und Toleranzen festgelegt.

Bildanalyse

Die Bildanalyse erfolgt durch Algorithmen, die die von der Bildgewinnung generierten Daten verarbeiten. Diese Algorithmen sind in die Bediensoftware integriert, mit der die Anlage gesteuert und die Inspektionskriterien festgelegt und gespeichert werden.

Entscheidung

Die Bauteile werden basierend auf den eingestellten Inspektionsparametern klassifiziert. Dabei können die Daten gespeichert und über eine SQL-Datenbank ausgewertet oder an ein übergeordnetes System übermittelt werden.

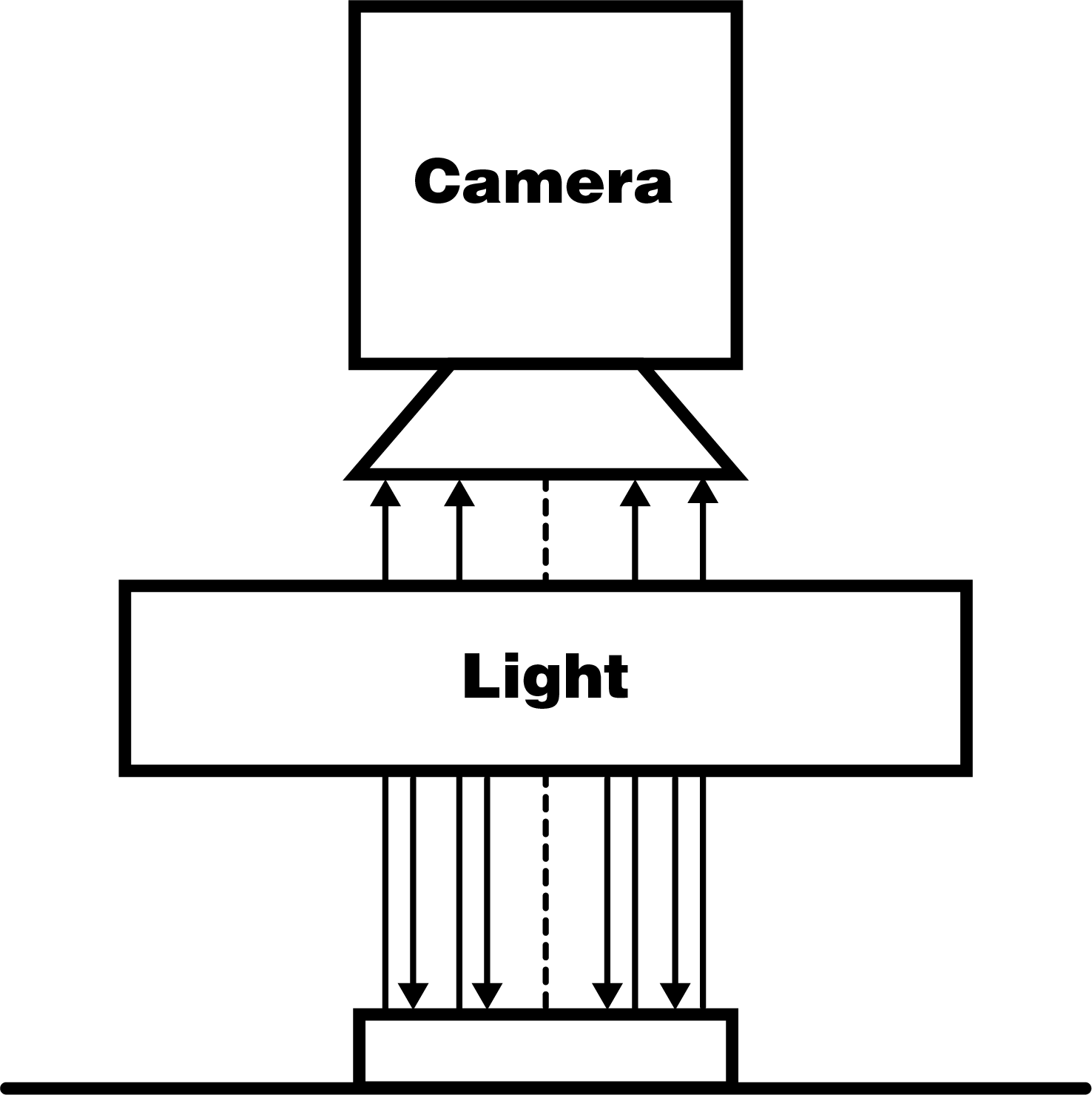

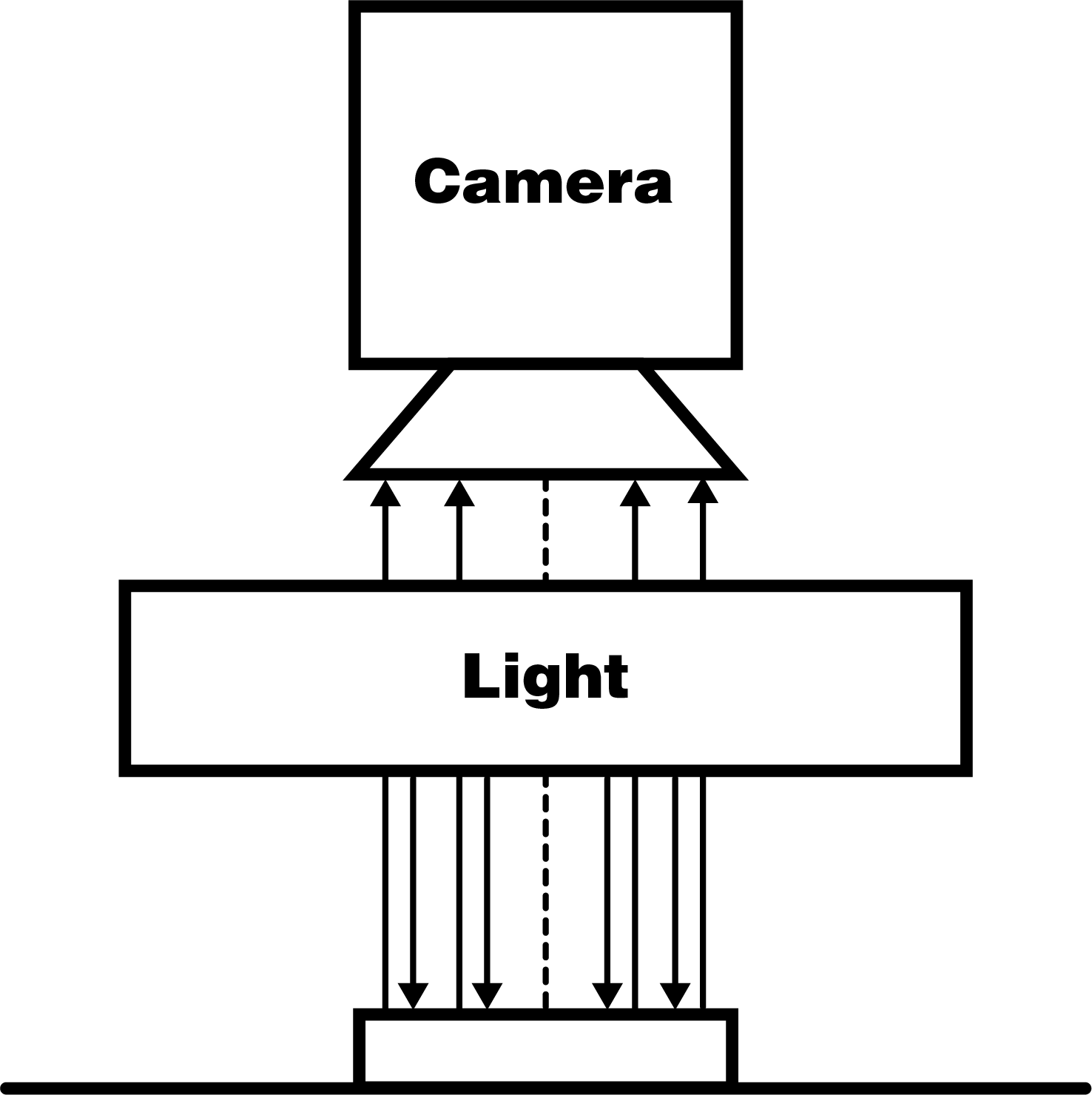

2D-Kameratechnik

Die 2D-Bilderfassung basiert auf dem Prinzip des menschlichen Auges – Licht fällt auf ein Objekt, wird reflektiert und vom Auge erfasst. In unseren Anlagen werden über eine künstliche Beleuchtung Lichtstrahlen erzeugt, die vom Objekt reflektiert und von der Kamera erfasst werden. Die Auswahl der passenden Beleuchtung und Kamera ist dabei abhängig vom Anwendungsfall.

Folgende Merkmale können mit der 2D-Kameratechnik überprüft werden:

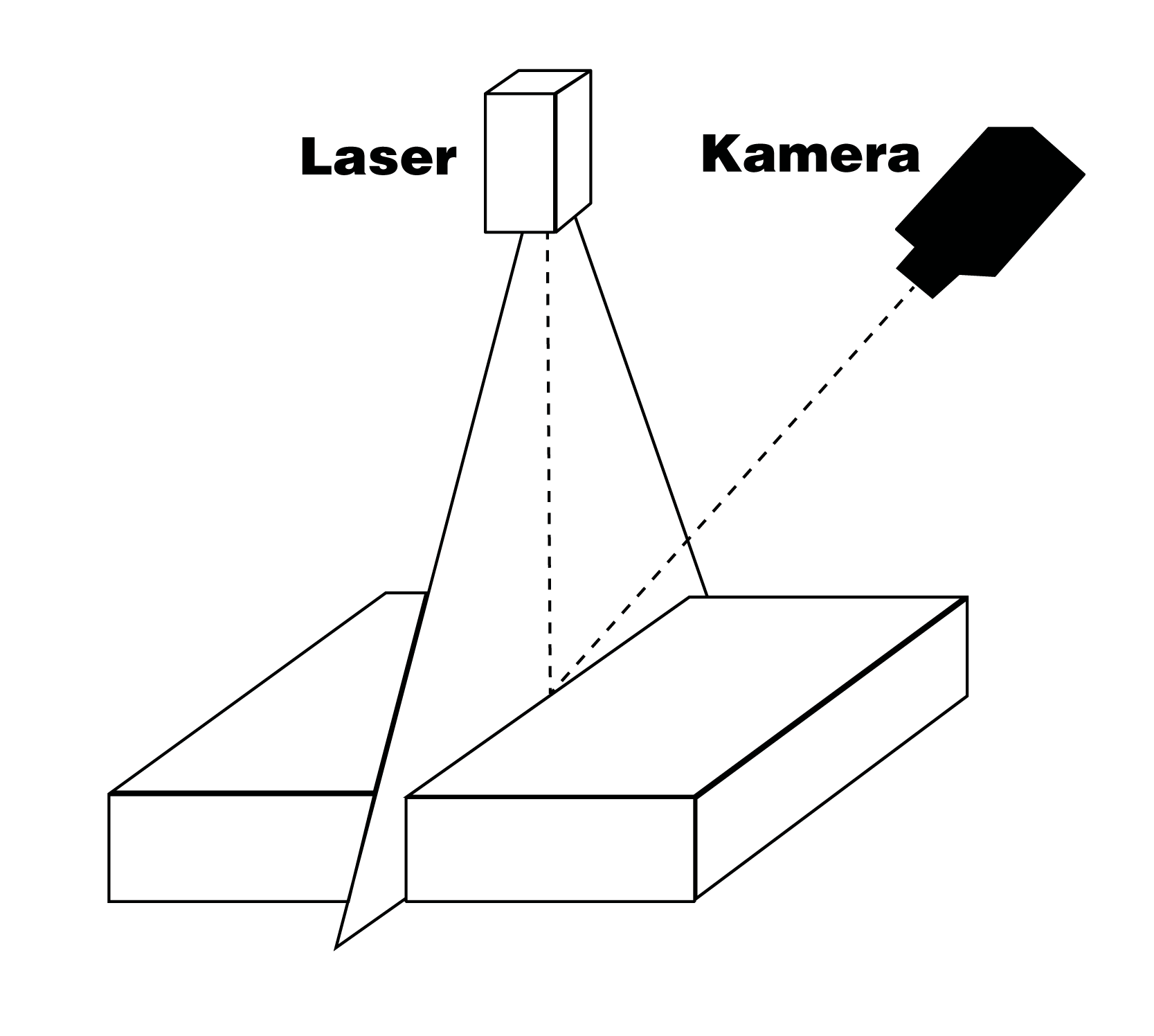

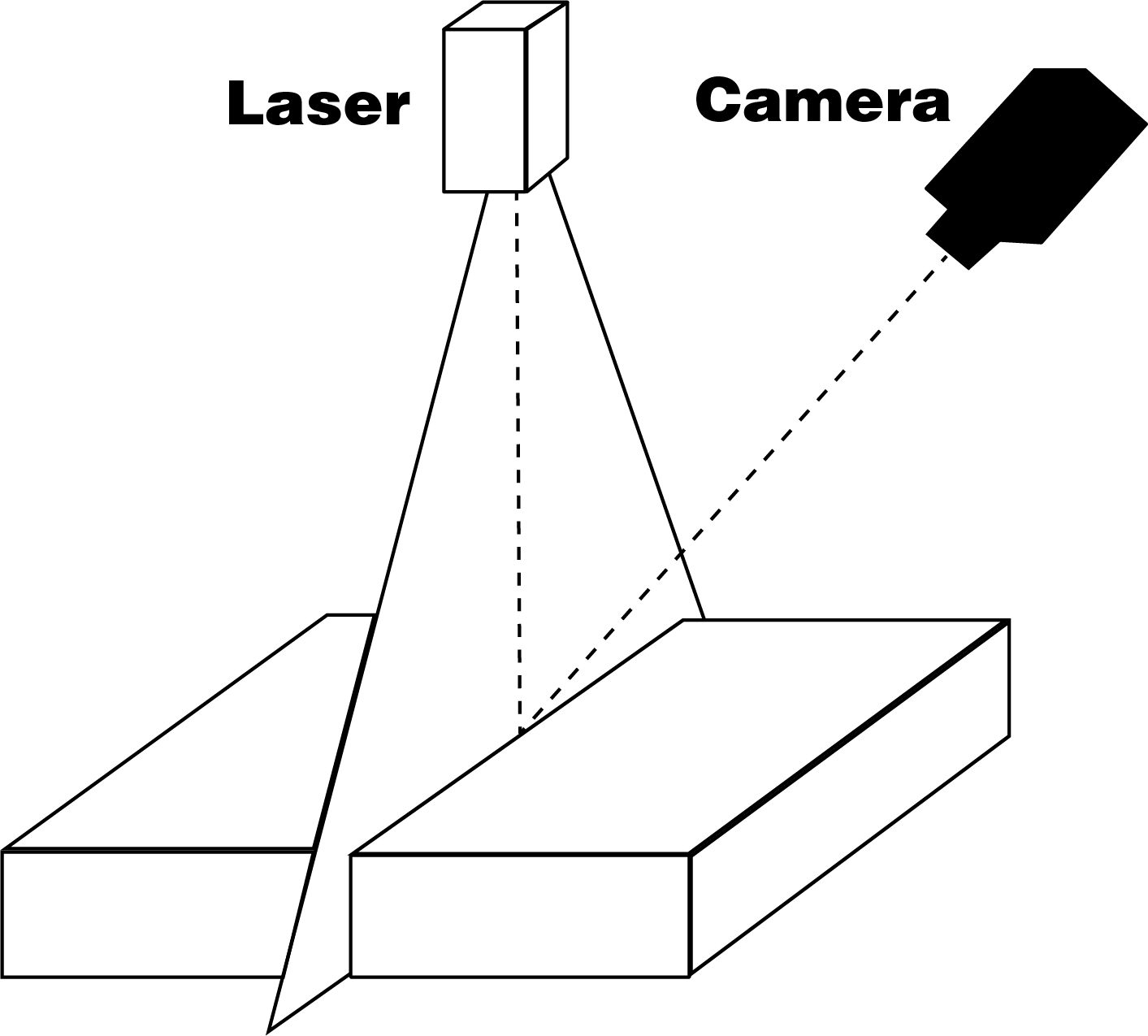

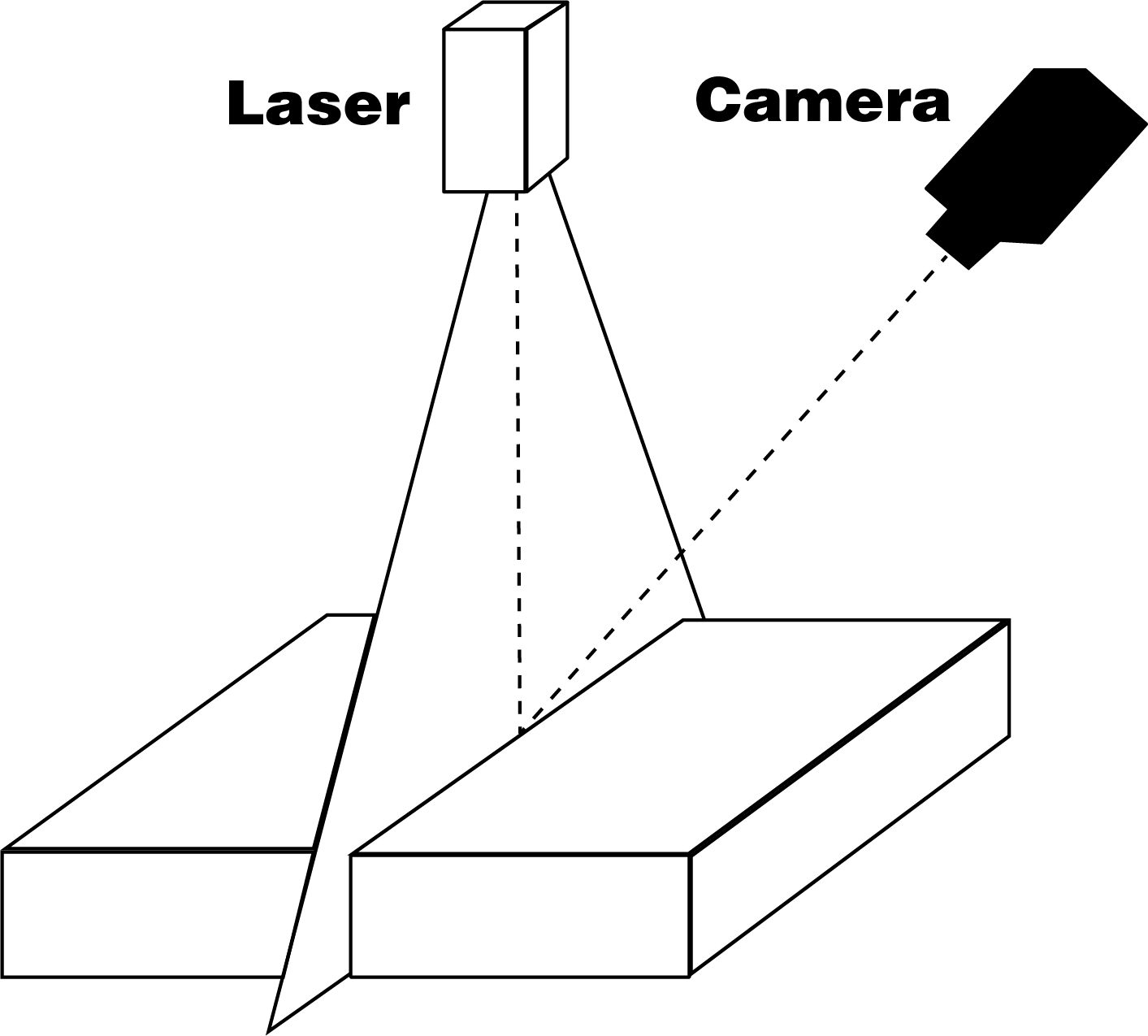

3D-Kameratechnik

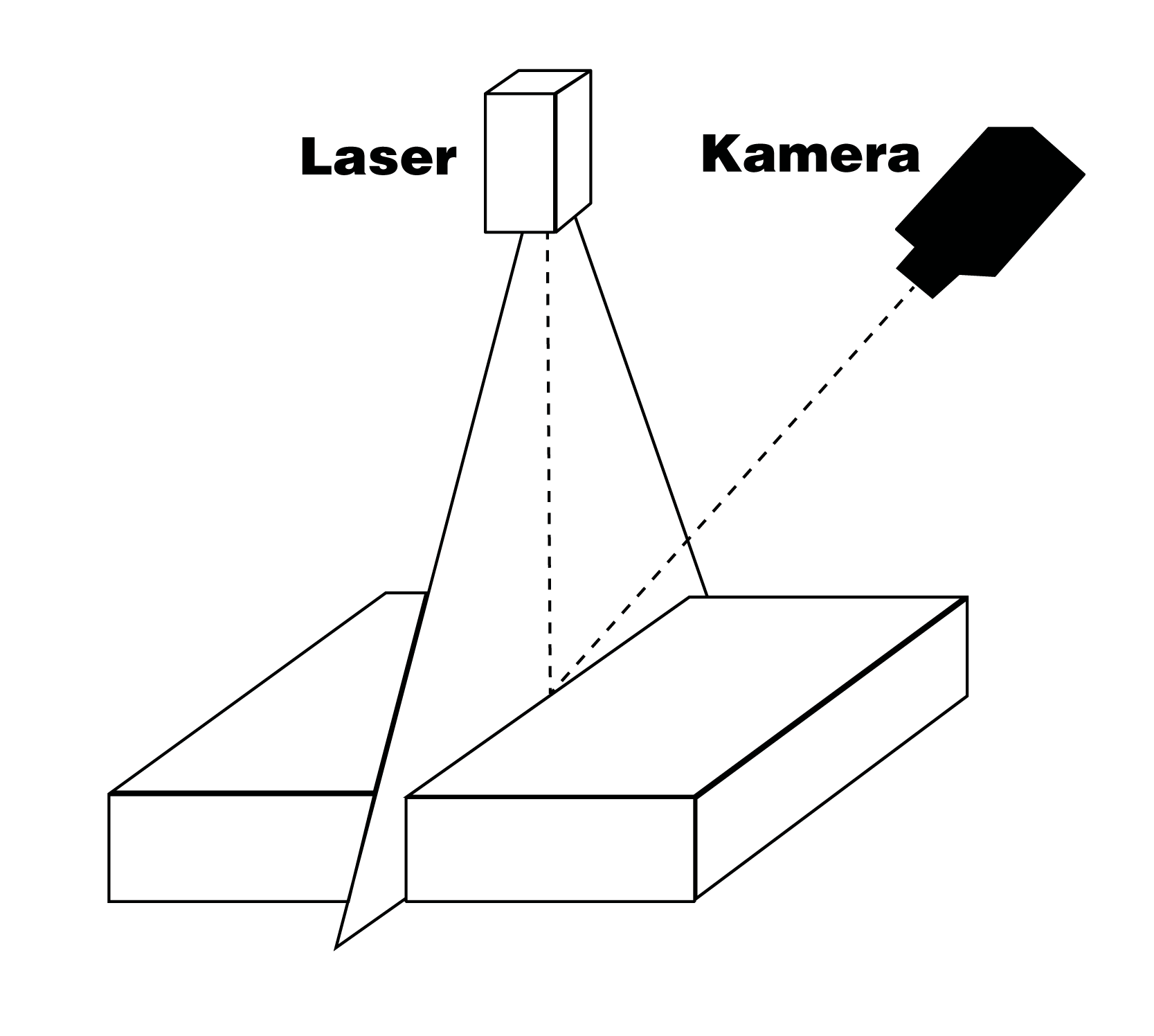

Die 3D-Bilderfassung knüpft dort an, wo die 2D-Kameratechnik ihre Grenzen erreicht, insbesondere mit Hinblick auf die Tiefenschärfe der Bilder, bzw. der Fähigkeit Höhenunterschiede zu erkennen. Zur Erstellung eines Höhenprofils wird das Bauteil mit einem Linienlaser beleuchtet. Der Laserstrahl wird reflektiert und von einer Kamera erfasst. Durch die Beleuchtung des Linienlasers, werden viele Schnittbilder erzeugt. Diese Teilinformationen des Bauteils werden durch die Software zu einem Gesamtobjekt zusammengesetzt.

Folgende Merkmale können mit der 3D-Kameratechnik überprüft werden:

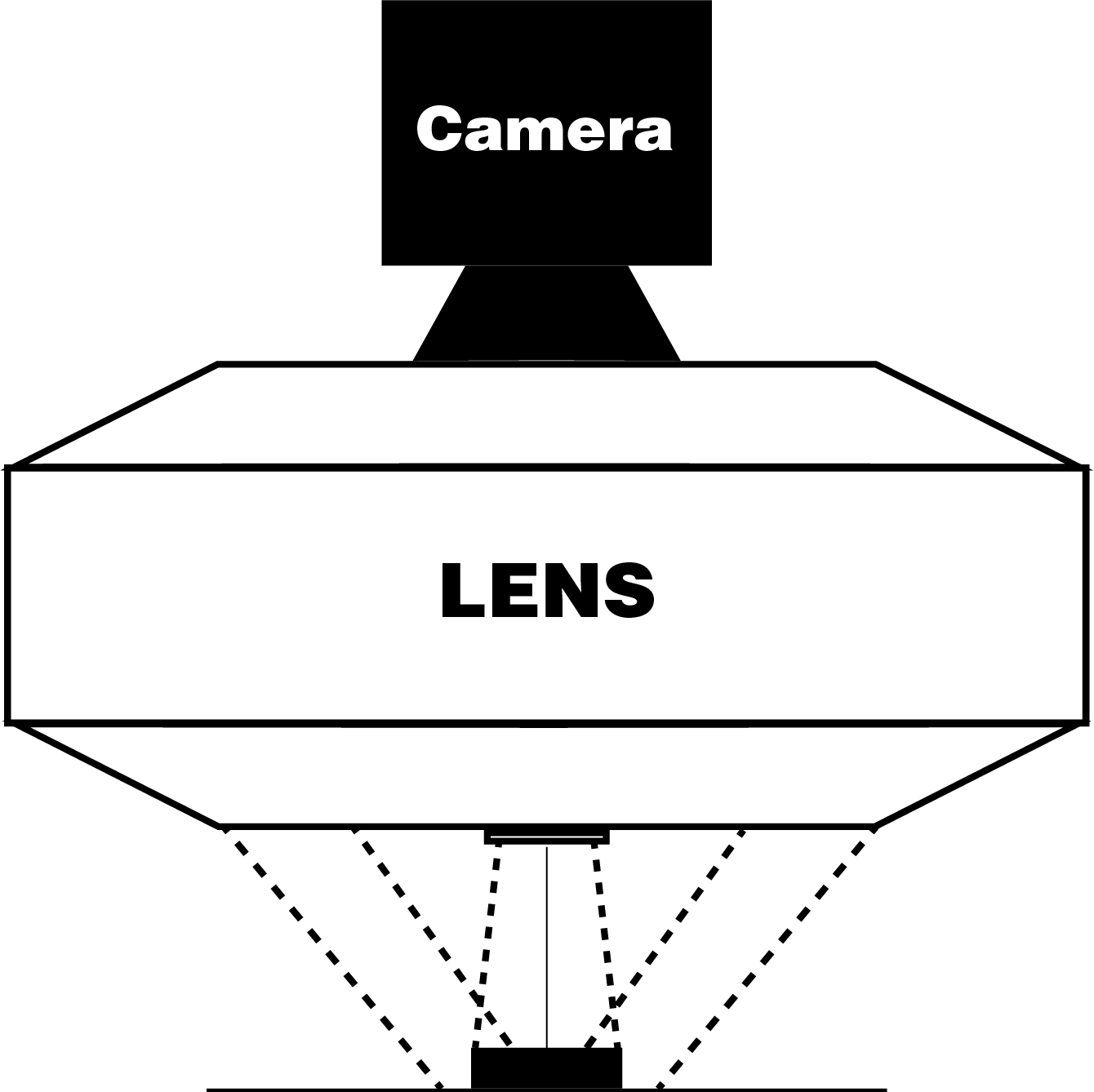

2D-Kameratechnik zur Randinspektion

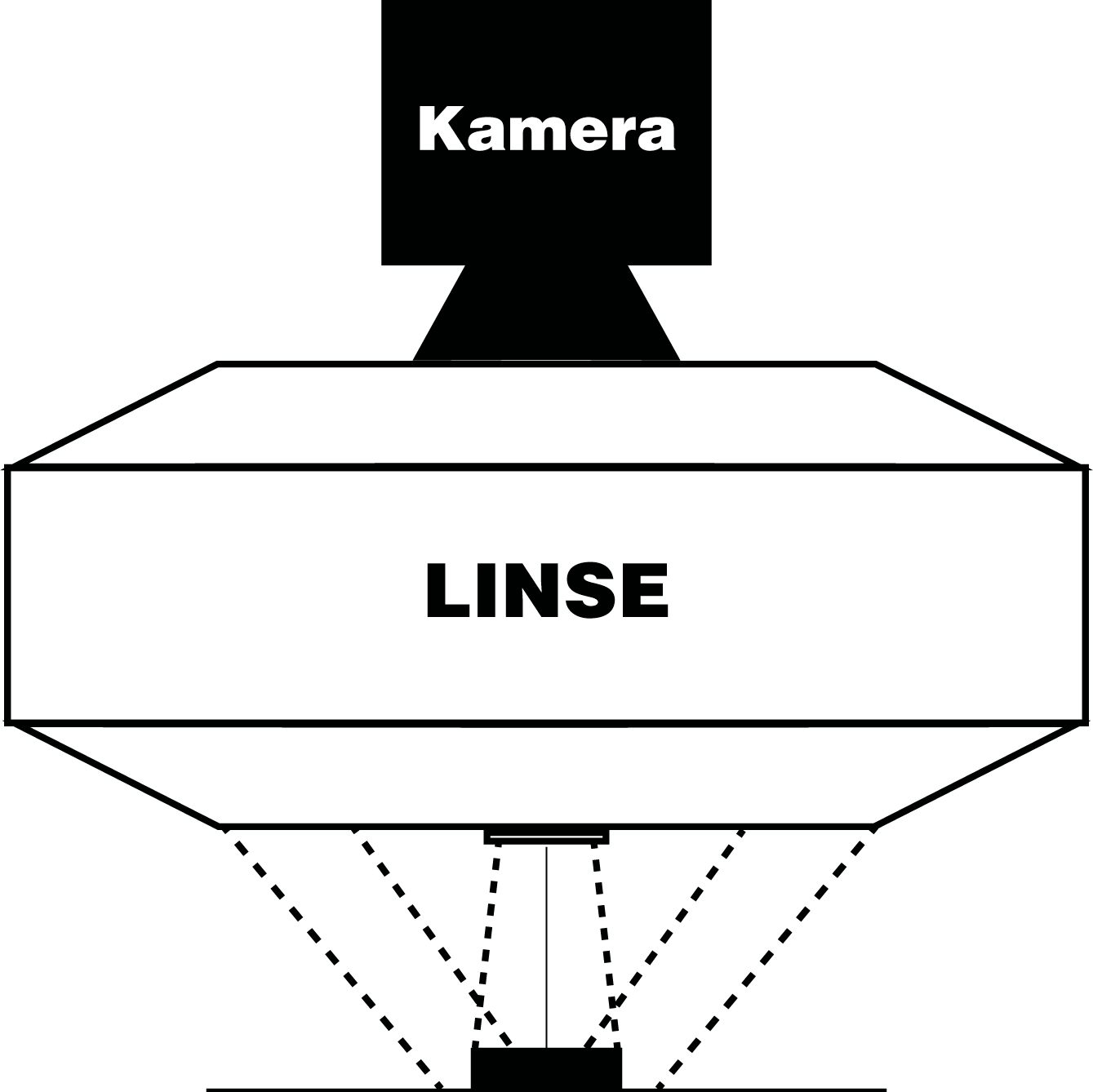

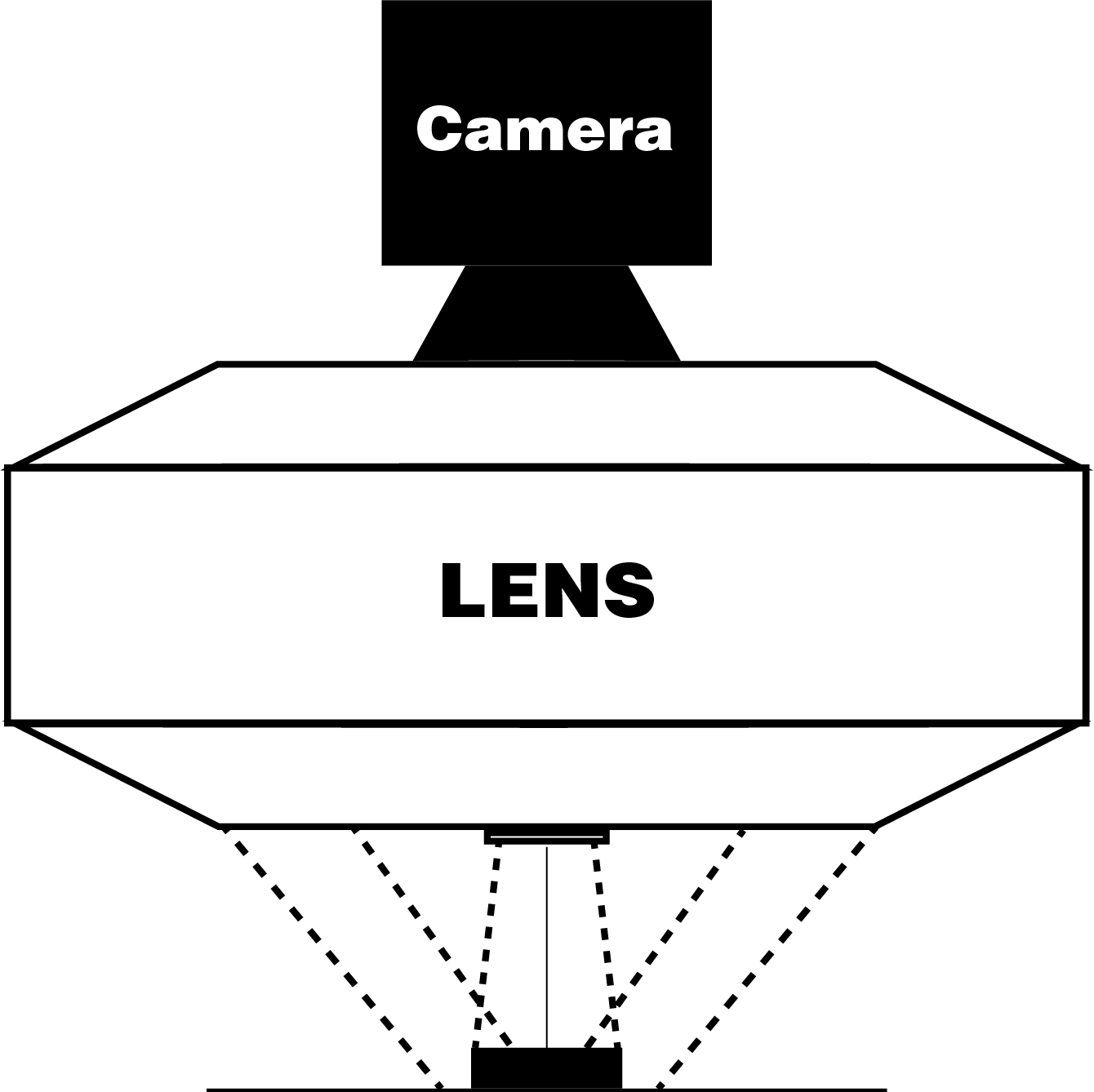

Aus geometrischen Gründen erfasst die 2D- und 3D-Kameratechnik nur die Ober- und Unterseite eines Objekts, nicht aber die Randflächen. Zur Inspektion der Randflächen wird eine spezielle 2D-Kamera in Kombination mit einem Ringlicht und einem katadioptrischen Objektiv eingesetzt.

Folgende Merkmale können mit der 2D-Kameratechnik zur Randinspektion überprüft werden:

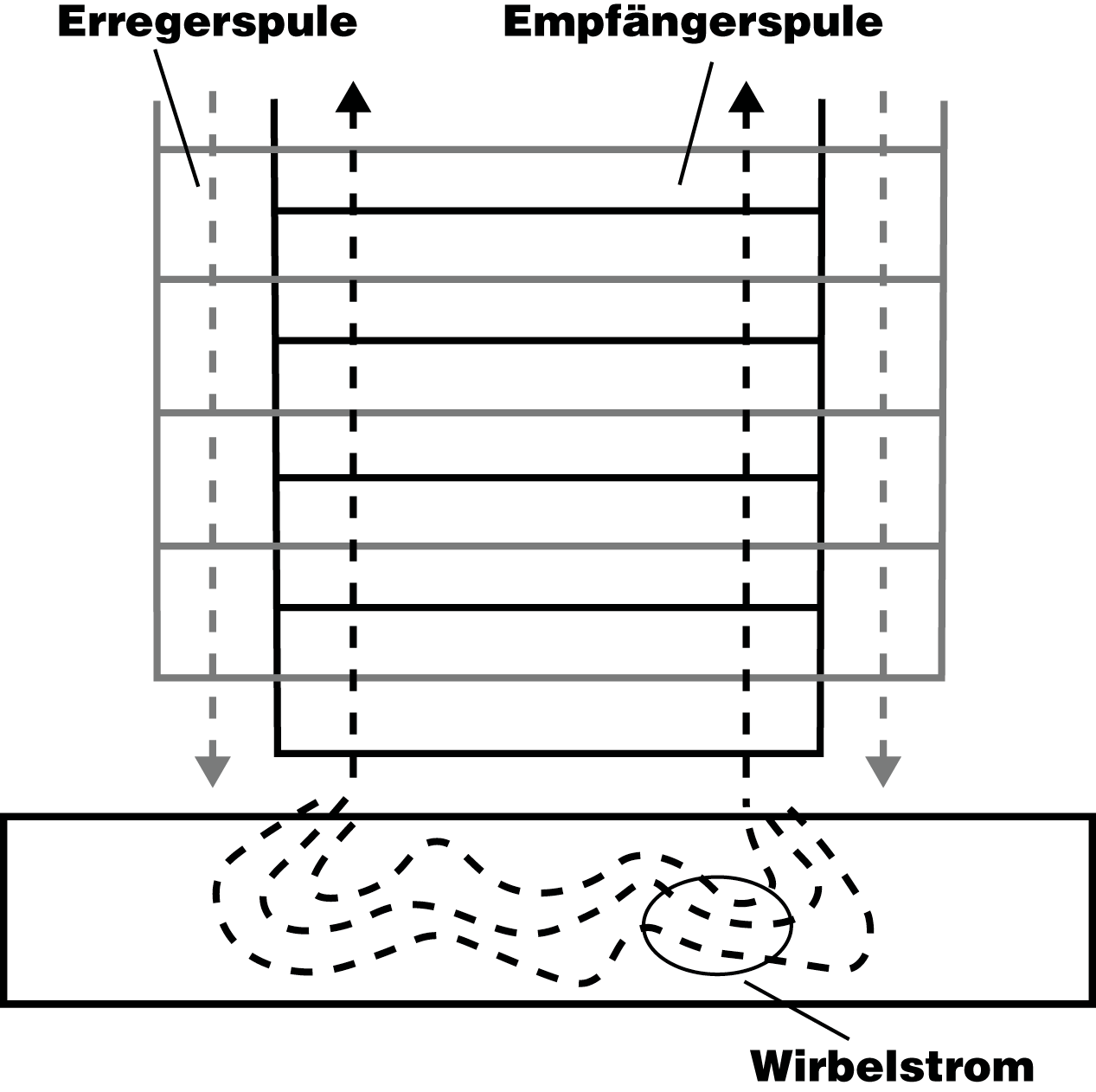

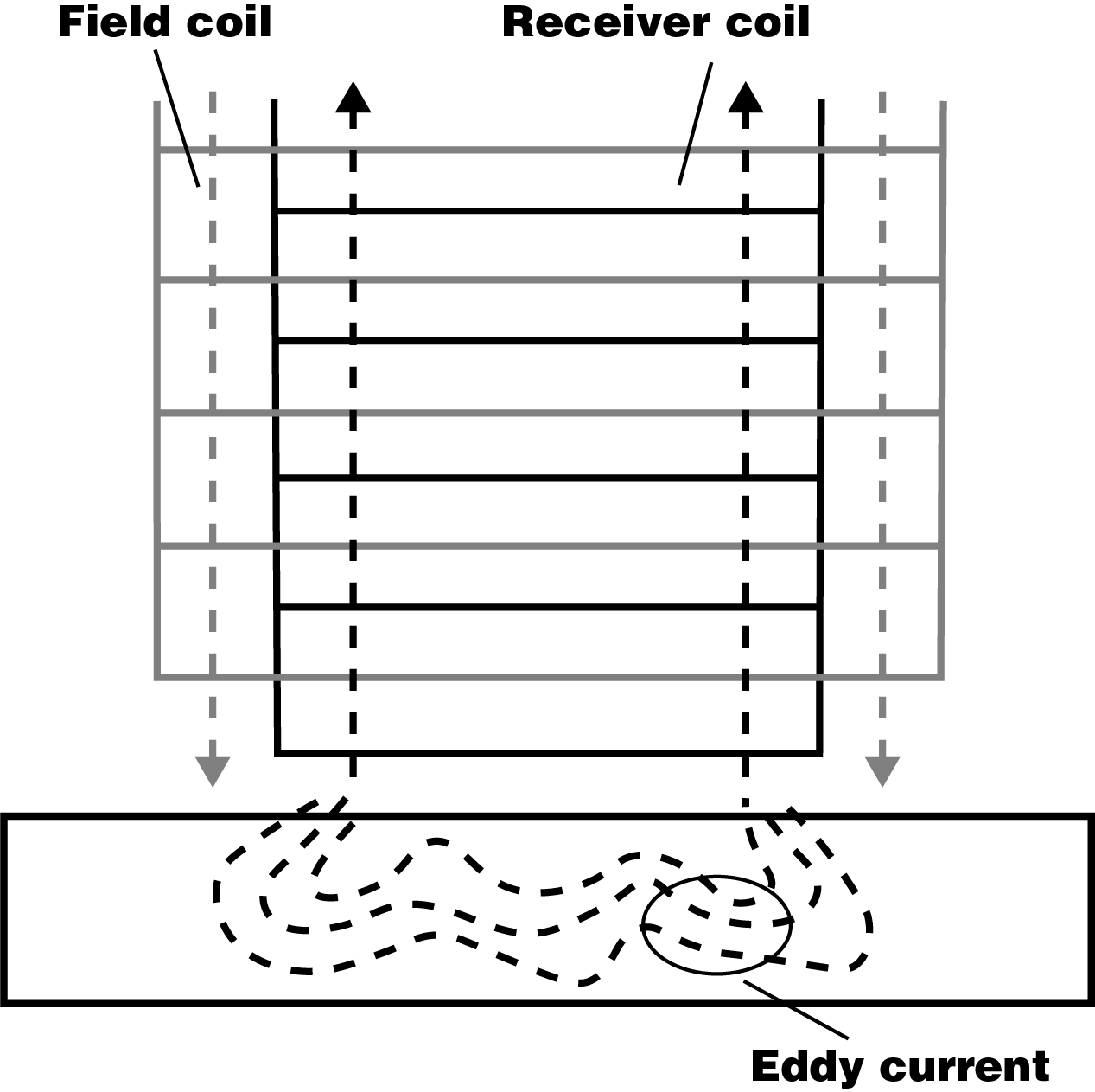

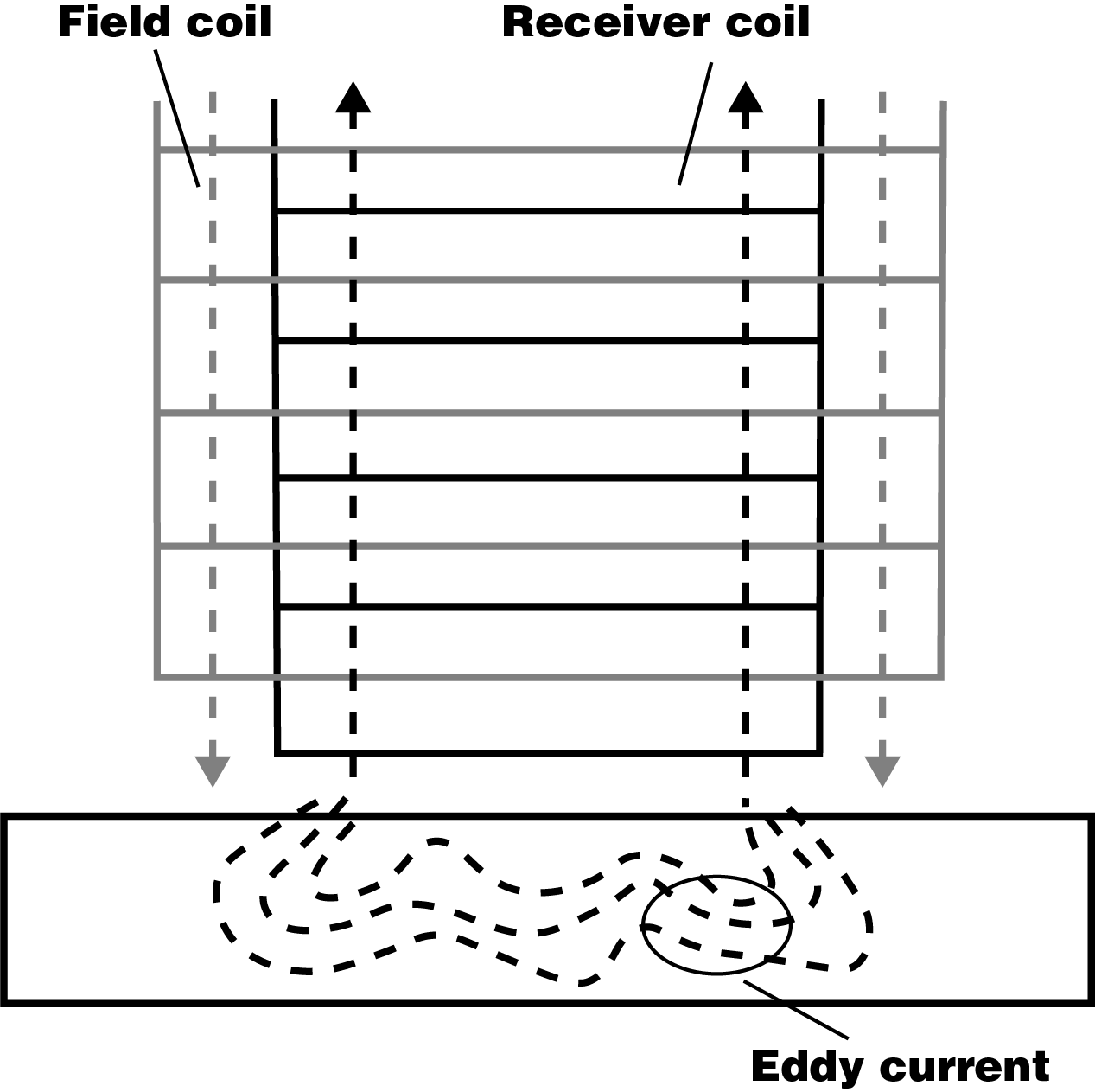

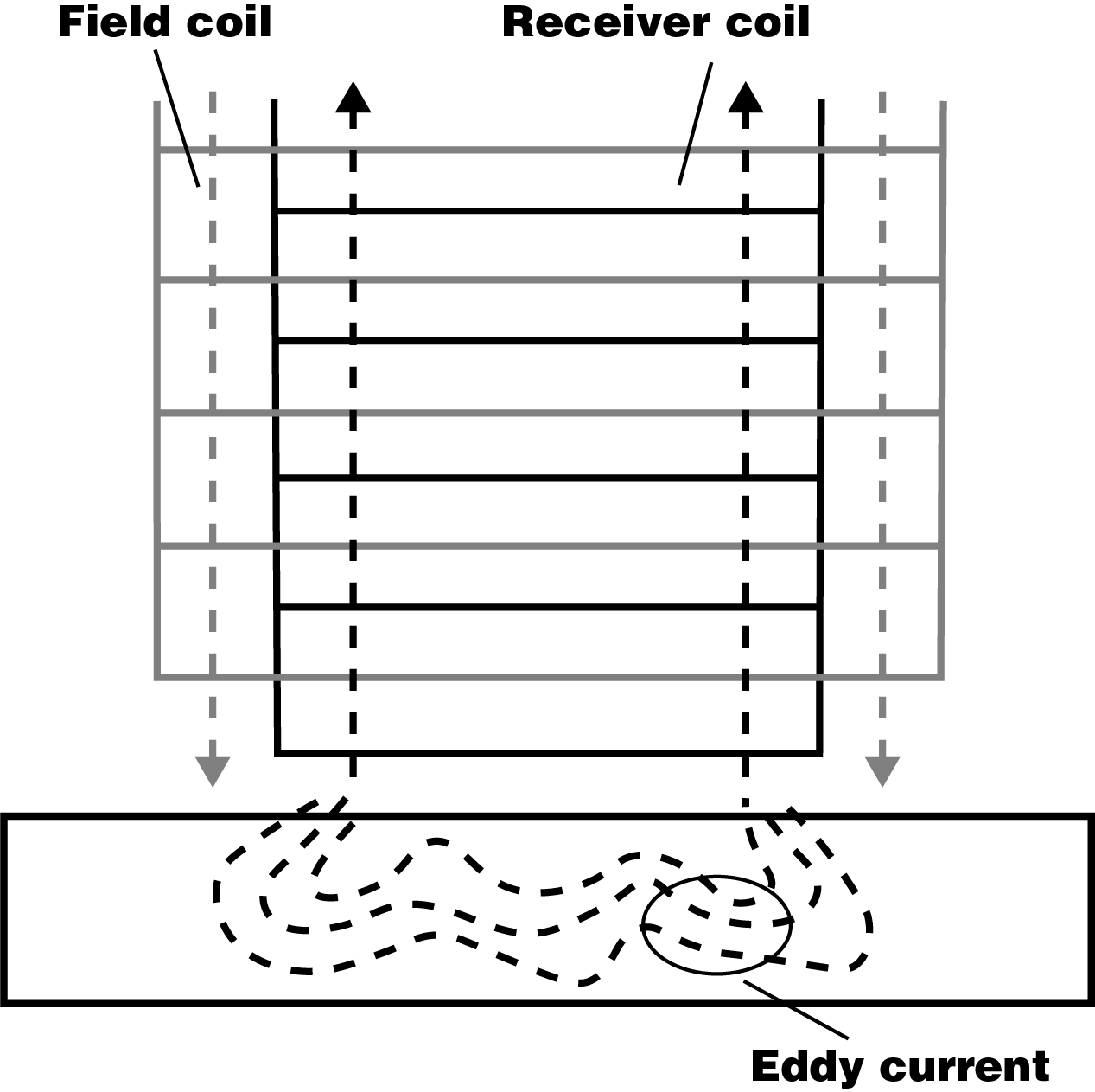

Wirbelstrommessung

Die Wirbelstrommessung ist ein zerstörungsfreies Verfahren zur Überprüfung metallischer Oberflächen. Mithilfe hochfrequenter, elektromagnetischer Wechselwirkungen lassen sich verschiedene Materialhärten sowohl manuell als auch automatisch erkennen und analysieren. Diese Methode spielt eine entscheidende Rolle in der Qualitätssicherung, da sie den mechanischen Widerstand eines Werkstoffs gegen das Eindringen eines anderen Körpers misst.

EMS-Sensoren

Dieses Messprinzip zur Überprüfung der Elektromagnetischen Signatur wird heute weltweit in Automaten eingesetzt, in denen man mit Münzen bezahlt. Durch die induktive Prüfung der Münze, bzw. Münzronde werden Erkenntnisse gewonnen über die Materialzusammensetzung und/oder Beschichtung der Münze/Ronde. Die Messwerte des einzelnen Objektes werden mit einer Materialdatenbank abgeglichen und abhängig von der Abweichung zu den Referenzen, bzw. der als akzeptablen definieren Abweichung als gut oder schlecht bewertet.

Inspection

The same requirements apply for an optical inspection as for the human eye. It is important to describe the component, define the characteristics to be tested and specify the tolerances.

Handling

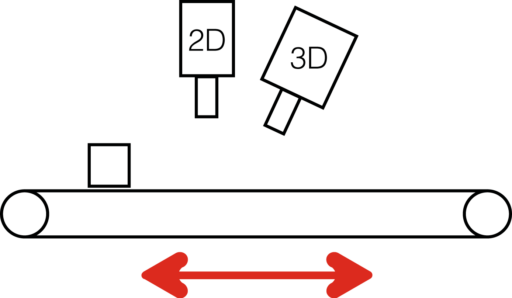

The variety of components and the desired degree of automation make component handling crucial. Transport and precise positioning under the inspection tool are crucial for optimum inspection results.

Image acquisition

Image acquisition includes the selection of lighting and camera technology. The type and sensitivity of the components are determined according to the previously defined test characteristics and tolerances.

Image analysis

The image analysis is performed by algorithms that process the data generated by the image acquisition. These algorithms are integrated into the operating software, which is used to control the system and define and save the inspection criteria.

Decision

The components are classified based on the set inspection parameters. The data can be stored and analyzed via an SQL database or transmitted to a higher-level system.

2D camera technology

2D image capture is based on the principle of the human eye – light falls on an object, is reflected and captured by the eye. In our systems, artificial lighting is used to generate light beams that are reflected by the object and captured by the camera. The choice of suitable lighting and camera depends on the application.

The following features can be checked using 2D camera technology:

3D camera technology

3D image capture picks up where 2D camera technology reaches its limits, particularly with regard to the depth of field of the images and the ability to recognize differences in height. To create a height profile, the component is illuminated with a line laser. The laser beam is reflected and captured by a camera. The illumination of the line laser generates many sectional images. This partial information of the component is put together by the software to form an overall object.

The following features can be checked using 3D camera technology:

2D camera technology for edge inspection

For geometric reasons, 2D and 3D camera technology only captures the top and bottom of an object, but not the edges. A special 2D camera in combination with a ring light and a catadioptric lens is used to inspect the edge surfaces.

The following features can be checked using 2D camera technology for edge inspection:

Eddy current measurement

Eddy current measurement is a non-destructive method for testing metallic surfaces. With the help of high-frequency electromagnetic interactions, different material hardnesses can be detected and analyzed both manually and automatically. This method plays a decisive role in quality assurance, as it measures the mechanical resistance of a material against the penetration of another body.

EMS sensors

This measuring principle for checking the electromagnetic signature is used worldwide in vending machines in which coins are used for payment. Inductive testing of the coin or coin blank provides information about the material composition and/or coating of the coin/blank. The measured values of the individual object are compared with a material database and assessed as good or bad depending on the deviation from the references or the deviation defined as acceptable.

Own training workshop

“More independence, more individual learning!” We give our trainees the opportunity to familiarize themselves independently with the production process and actively participate in it from the very beginning. They are guided by our experienced trainers and can practise their ability to reflect and self-monitor.

Individual further training opportunities

“More knowledge, more opportunities!” Through targeted training, you can expand your skills, strengthen your employability and advance your career with us.

Flat hierarchies

“More freedom, more speed!” With us, decision-making processes are shorter, communication is more direct and the sense of togetherness is stronger. No long back and forth – just get started!

Employer-financed company pension

Depending on your length of service, you will receive a lump sum at the start of your pension – a nice extra for your future!

Company pension scheme

More pension, fewer worries!” Our company pension plan offers you additional financial security in retirement – without any major outlay. The employer subsidy helps you build up your pension, so you can sit back and relax.

Bicycle leasing

More freedom, more fitness!” With a JobRad you can not only make your commute to work environmentally friendly, but also go on relaxed bike rides in your free time – this way you promote your health.

One-shift operation

“One shift, more serenity!” With fixed shift work, you can rely on clear working hours. No constant switching between early, late and night shifts – that means more stability and less stress.

Vacation and Christmas bonus

“Extra money, extra joy!” Vacation and Christmas bonuses are like little gifts that bring you joy all year round. Whether you use it to top up your travel fund or treat yourself to something special – financial extras ensure a good mood and motivation.

Flexible working hours

“Work flexibly, live flexibly!” Whether you start earlier to have the afternoon free or start later to avoid traffic – flexibility increases satisfaction and productivity.

30 days vacation

“More vacation, more power!” With a generous 30 days’ vacation, you can really relax, explore the world and experience new adventures – without stress and with plenty of sunshine in your heart.

35 hours week

“More free time, less stress!” With a 35-hour week, you have enough time for hobbies, family and spontaneous trips – without the stress of overtime.

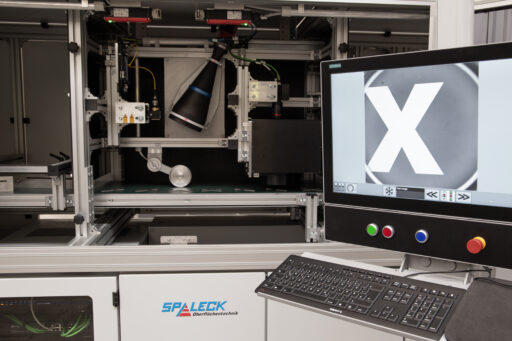

Inspection technology for maximum precision

The material handling is realized by our in-house machine construction in coordination with the requirements of the inspection technology.

Our proprietary software solution makes it possible to solve the inspection task in a customer-specific manner and includes the option of defect classification and statistical evaluation.