Internship

An internship with us is the perfect opportunity to gain your first professional experience and gain exciting insights into the world of work. Come along and discover what you’re made of.

Types of internship:

Day internships, school internships, voluntary internships

Application deadline:

6 months before

Education

Start your career with an apprenticeship with us and become part of the future of tomorrow! We offer you exciting tasks and the opportunity to develop your skills in a motivated team.

Start of training:

September, 01

Application deadline:

Spring/summer of the previous year

Dual study program

As a cooperation partner of the Westphalian University of Applied Sciences, we offer the Bachelor’s degree courses in Mechanical Engineering and Mechatronics in combination with an apprenticeship.

Practical semester

An internship semester with us is your chance to gain real work experience and apply your knowledge directly. Use this opportunity to gain valuable insights into the world of work and expand your network.

Thesis

Are you looking for a place to write your thesis? We not only offer exciting use cases, but also support you in the concrete design of your topic.

Working student job

A working student job with us is the perfect entry into the professional world! Gain practical experience, make valuable contacts and become part of our team.

Are you interested in technical matters and want to put your manual skills to the test? As an industrial mechanic, you will produce assemblies and assemble them into systems and machines.

Key training data:

Are you passionate about technology and can find a solution to any problem? As a mechatronics technician, you build complex mechatronic systems from mechanical, electrical and electronic components.

Key training data:

Do you have a good understanding of mathematics and are you very precise and conscientious? As a cutting machine operator, you will manufacture components using exciting processes such as turning, milling and drilling.

Key training data:

Do you like to keep things tidy and are you a real organizational talent? As a warehouse logistics specialist, you are responsible for the movement of goods and optimizing the flow of materials in the company.

Key training data:

Are you fascinated by the combination of design and technology? As a technical product designer, you will develop technical designs of various sizes – from the smallest component to complex production systems.

Key training data:

Do you like to keep an overview and ensure that everything runs smoothly? As an industrial clerk, you will gain an insight into all commercial departments – from accounting and purchasing to sales.

Key training data:

Take a look behind the scenes and discover the exciting world of surface finishing! You can find out when the next company tour takes place on our Instagram channel or at one of the next trainee fairs. We look forward to getting to know you!

Any questions?

If you have any questions about apprenticeship, internships, etc., I’m the right person to talk to. Feel free to contact me!

Lukas Arndt

Head of HR and Accounting

+49 (0)2871 9500-138

+49 (0)162 138 28 29

l.arndt@spaleck.biz

SPALECK Oberflächentechnik

GmbH & Co. KG

Schlavenhorst 117

D-46395 Bocholt

Own training workshop

“More independence, more individual learning!” We give our trainees the opportunity to familiarize themselves independently with the production process and actively participate in it from the very beginning. They are guided by our experienced trainers and can practise their ability to reflect and self-monitor.

Individual further training opportunities

“More knowledge, more opportunities!” Through targeted training, you can expand your skills, strengthen your employability and advance your career with us.

Flat hierarchies

“More freedom, more speed!” With us, decision-making processes are shorter, communication is more direct and the sense of togetherness is stronger. No long back and forth – just get started!

Employer-financed company pension

Depending on your length of service, you will receive a lump sum at the start of your pension – a nice extra for your future!

Company pension scheme

More pension, fewer worries!” Our company pension plan offers you additional financial security in retirement – without any major outlay. The employer subsidy helps you build up your pension, so you can sit back and relax.

Bicycle leasing

More freedom, more fitness!” With a JobRad you can not only make your commute to work environmentally friendly, but also go on relaxed bike rides in your free time – this way you promote your health.

One-shift operation

“One shift, more serenity!” With fixed shift work, you can rely on clear working hours. No constant switching between early, late and night shifts – that means more stability and less stress.

Vacation and Christmas bonus

“Extra money, extra joy!” Vacation and Christmas bonuses are like little gifts that bring you joy all year round. Whether you use it to top up your travel fund or treat yourself to something special – financial extras ensure a good mood and motivation.

Flexible working hours

“Work flexibly, live flexibly!” Whether you start earlier to have the afternoon free or start later to avoid traffic – flexibility increases satisfaction and productivity.

30 days vacation

“More vacation, more power!” With a generous 30 days’ vacation, you can really relax, explore the world and experience new adventures – without stress and with plenty of sunshine in your heart.

35 hours week

“More free time, less stress!” With a 35-hour week, you have enough time for hobbies, family and spontaneous trips – without the stress of overtime.

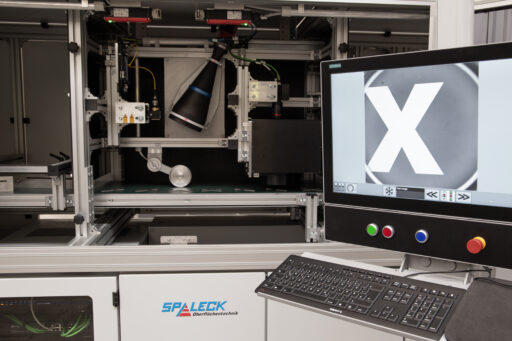

Inspection technology for maximum precision

The material handling is realized by our in-house machine construction in coordination with the requirements of the inspection technology.

Our proprietary software solution makes it possible to solve the inspection task in a customer-specific manner and includes the option of defect classification and statistical evaluation.

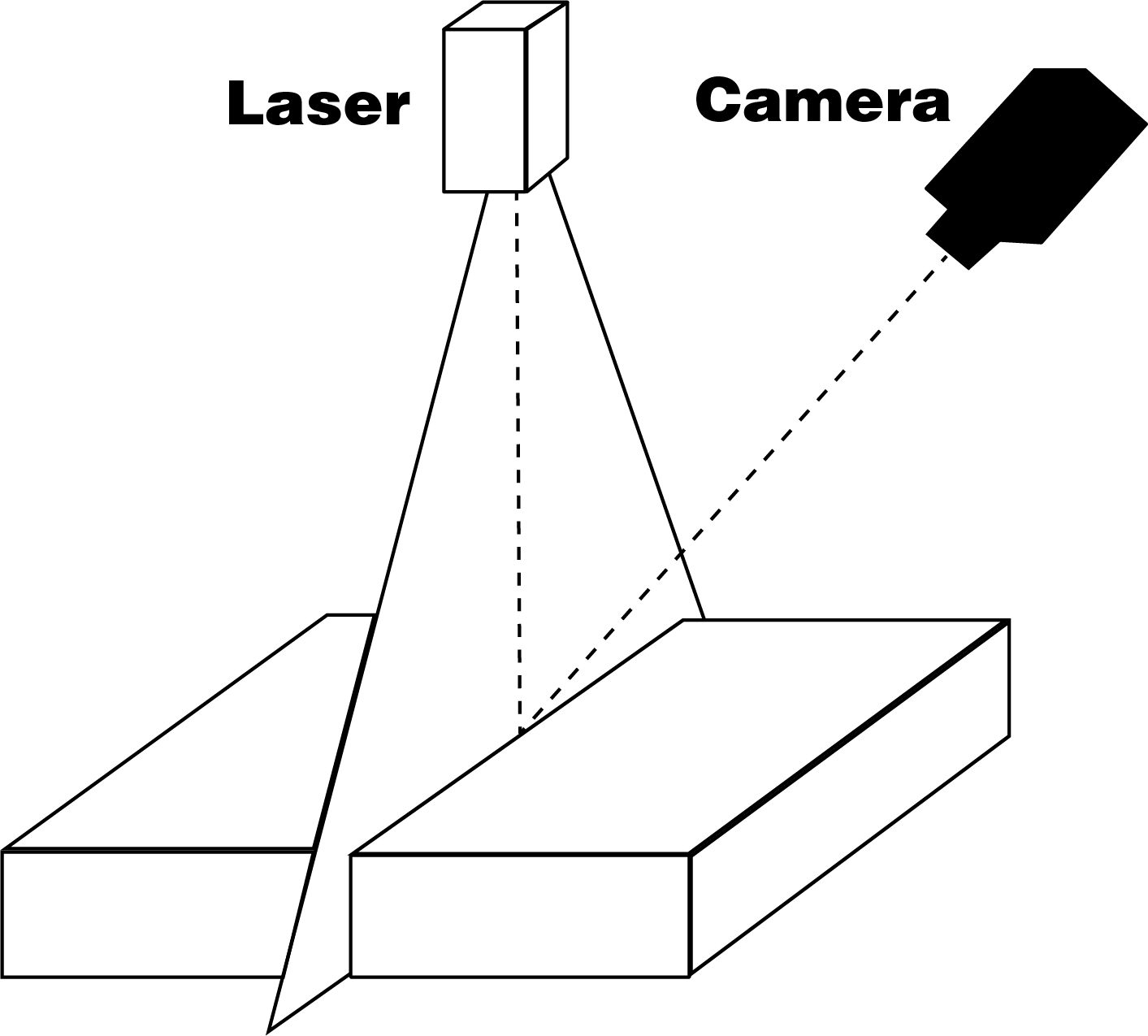

EMS sensors

This measuring principle for checking the electromagnetic signature is used worldwide in vending machines in which coins are used for payment. Inductive testing of the coin or coin blank provides information about the material composition and/or coating of the coin/blank. The measured values of the individual object are compared with a material database and assessed as good or bad depending on the deviation from the references or the deviation defined as acceptable.

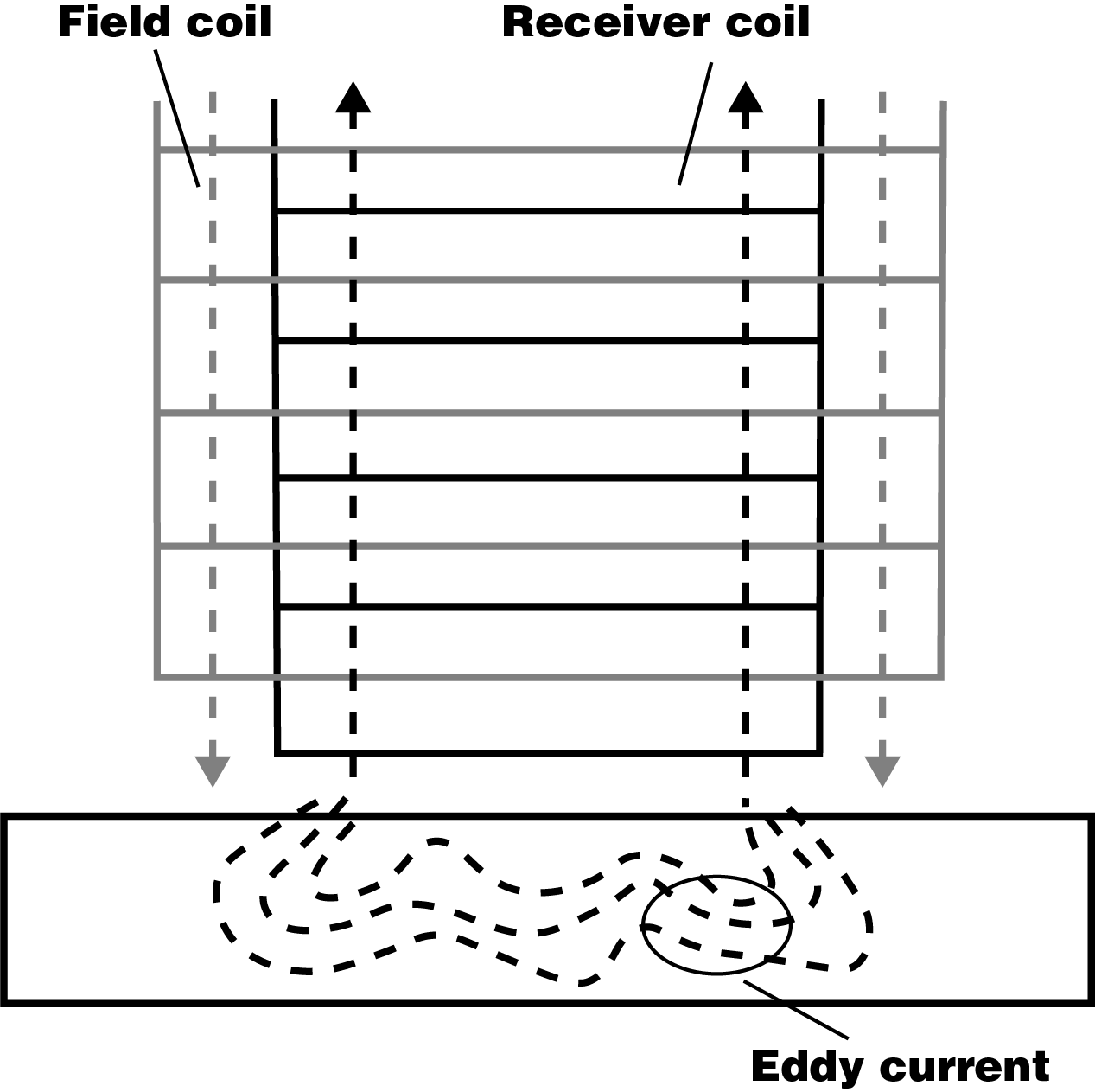

Eddy current measurement

Eddy current measurement is a non-destructive method for testing metallic surfaces. With the help of high-frequency electromagnetic interactions, different material hardnesses can be detected and analyzed both manually and automatically. This method plays a decisive role in quality assurance, as it measures the mechanical resistance of a material against the penetration of another body.

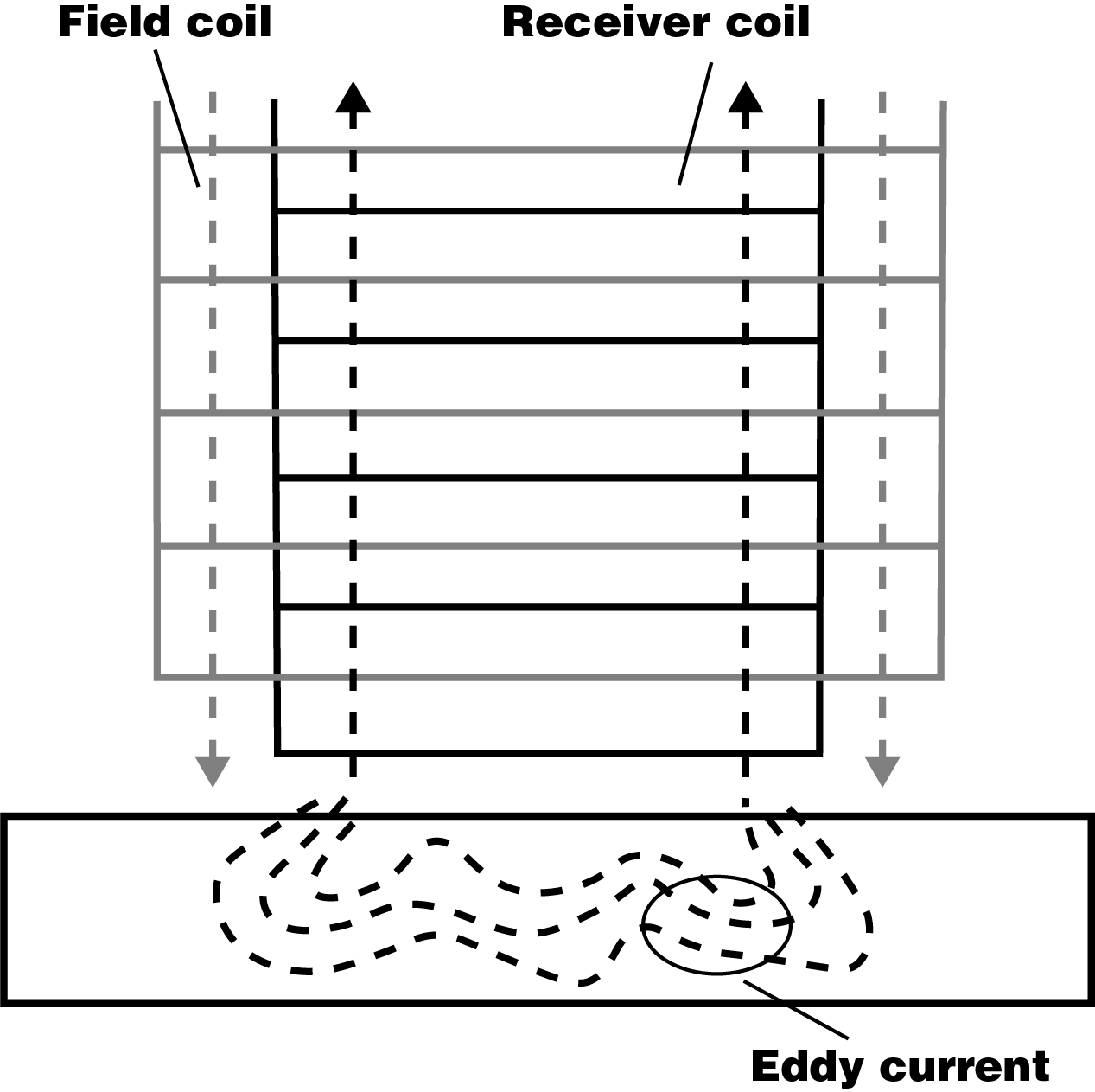

2D camera technology for edge inspection

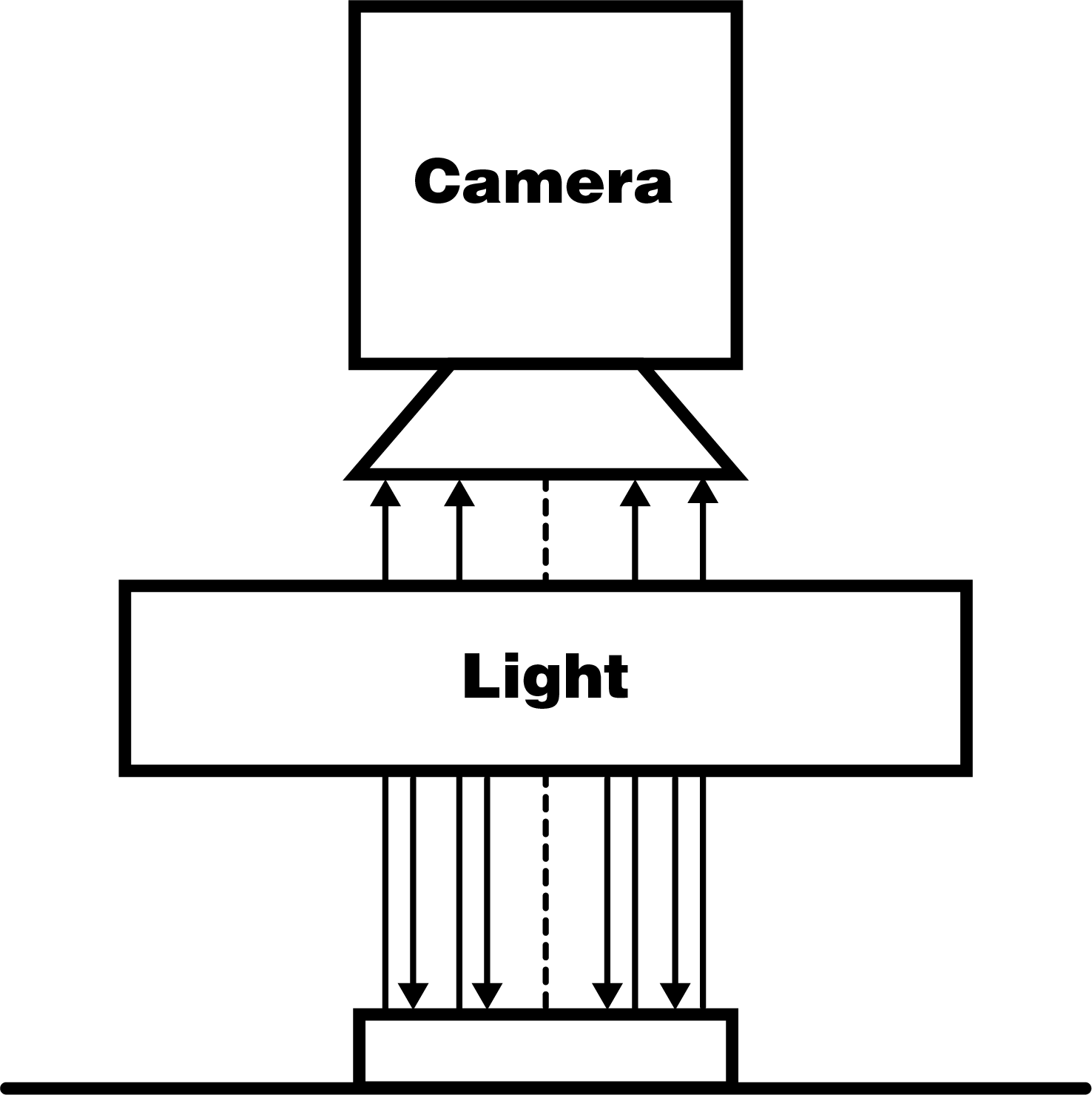

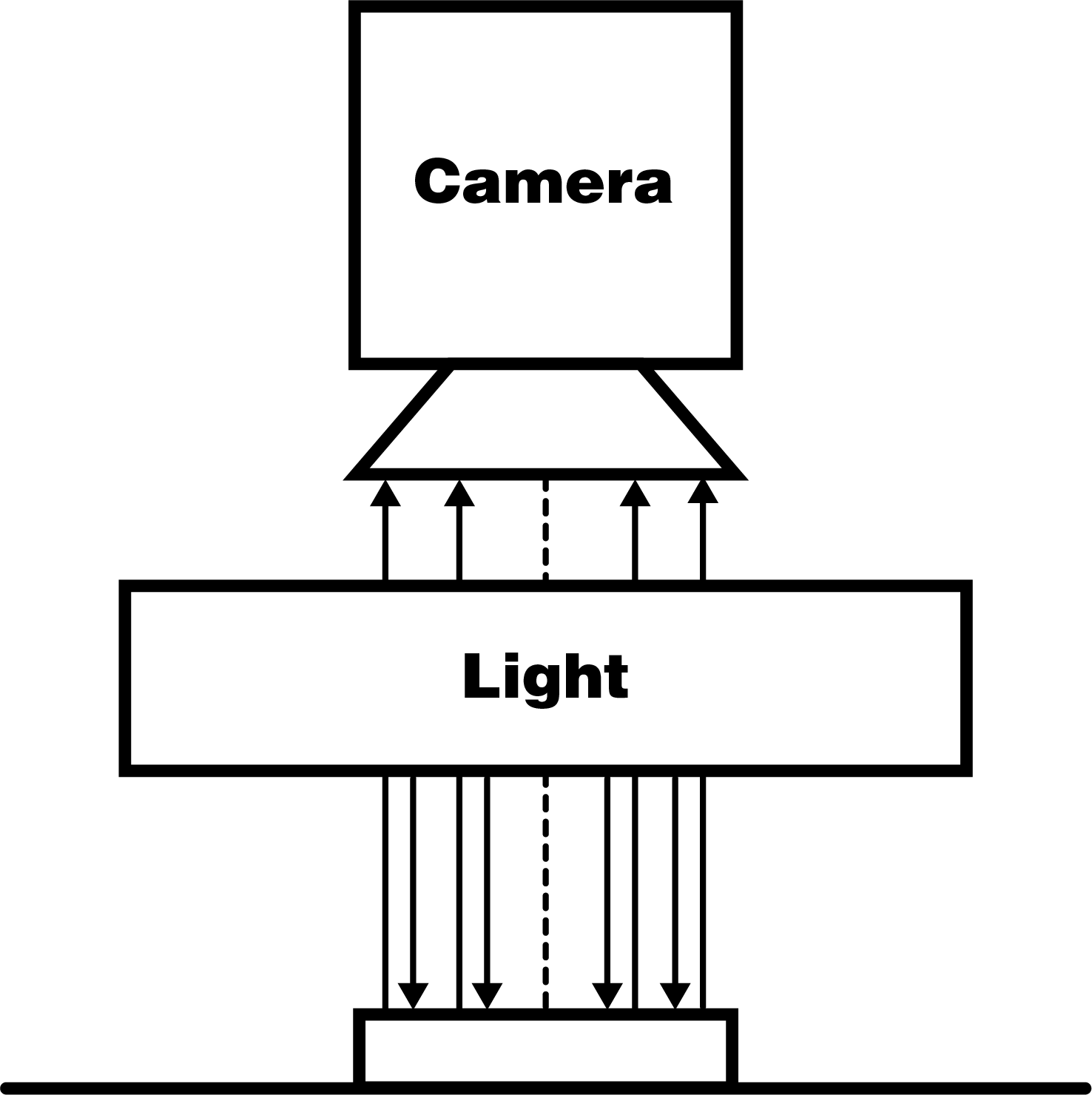

For geometric reasons, 2D and 3D camera technology only captures the top and bottom of an object, but not the edges. A special 2D camera in combination with a ring light and a catadioptric lens is used to inspect the edge surfaces.

The following features can be checked using 2D camera technology for edge inspection:

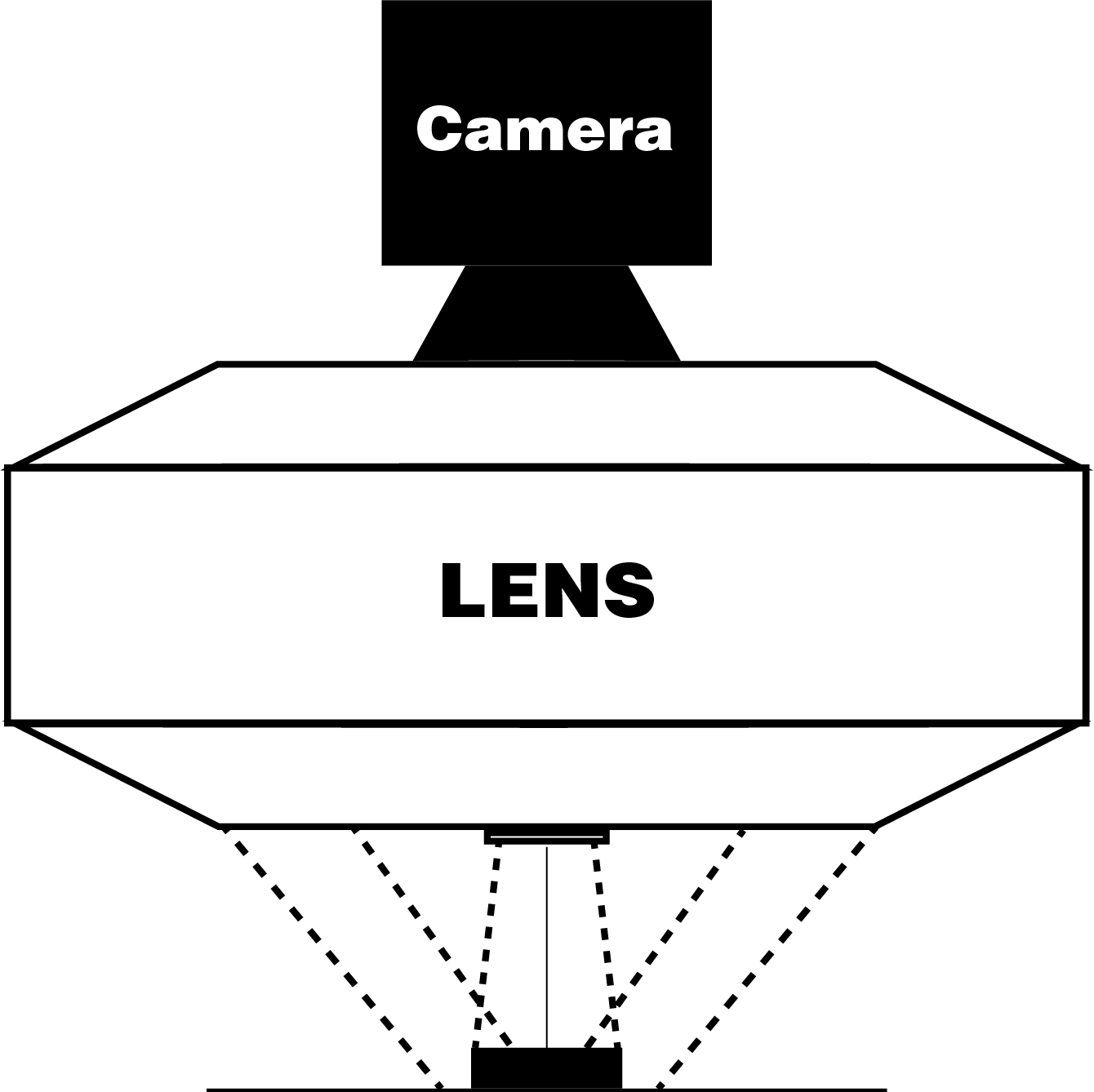

3D camera technology

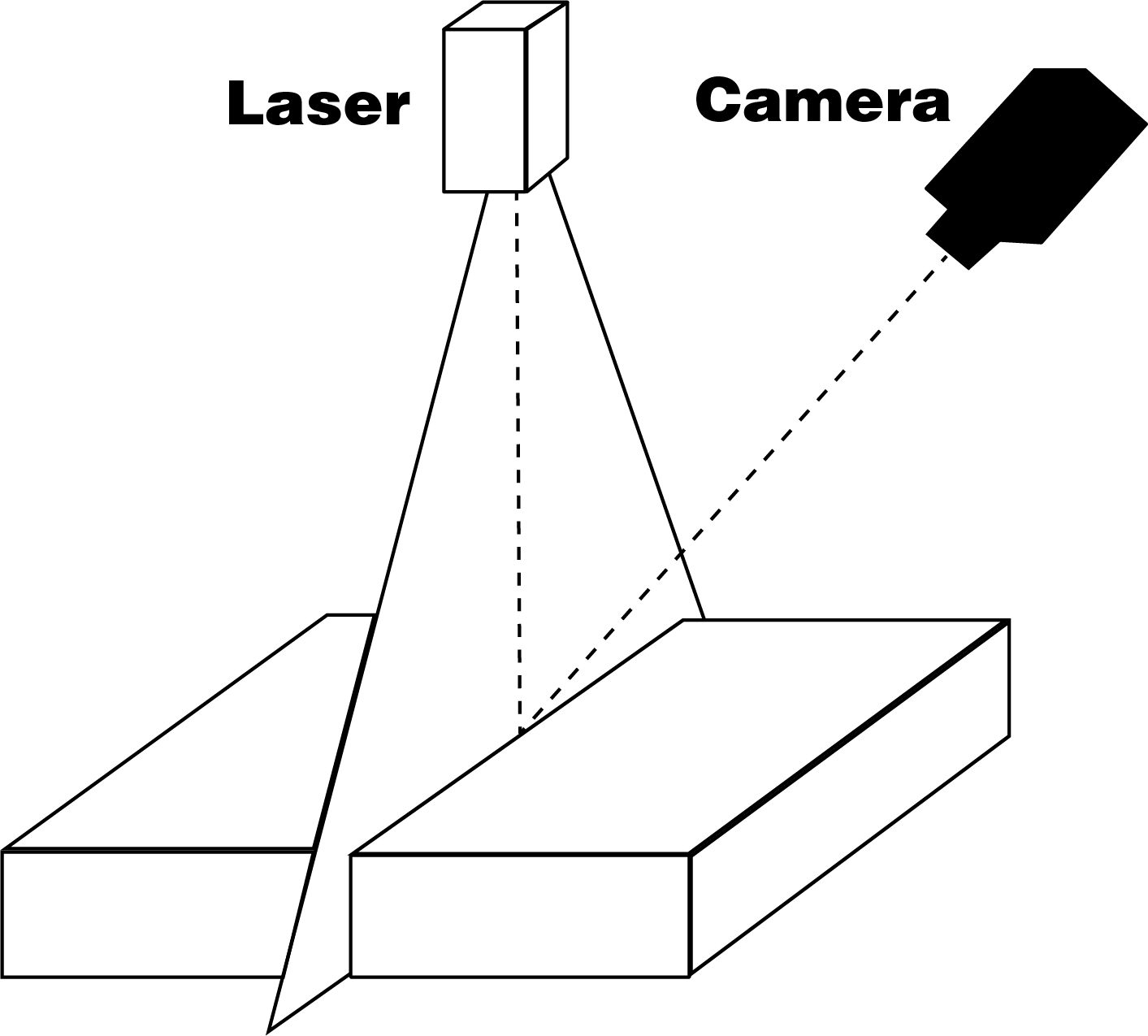

3D image capture picks up where 2D camera technology reaches its limits, particularly with regard to the depth of field of the images and the ability to recognize differences in height. To create a height profile, the component is illuminated with a line laser. The laser beam is reflected and captured by a camera. The illumination of the line laser generates many sectional images. This partial information of the component is put together by the software to form an overall object.

The following features can be checked using 3D camera technology:

2D camera technology

2D image capture is based on the principle of the human eye – light falls on an object, is reflected and captured by the eye. In our systems, artificial lighting is used to generate light beams that are reflected by the object and captured by the camera. The choice of suitable lighting and camera depends on the application.

The following features can be checked using 2D camera technology:

Decision

The components are classified based on the set inspection parameters. The data can be stored and analyzed via an SQL database or transmitted to a higher-level system.

Image analysis

The image analysis is performed by algorithms that process the data generated by the image acquisition. These algorithms are integrated into the operating software, which is used to control the system and define and save the inspection criteria.

Image acquisition

Image acquisition includes the selection of lighting and camera technology. The type and sensitivity of the components are determined according to the previously defined test characteristics and tolerances.

Handling

The variety of components and the desired degree of automation make component handling crucial. Transport and precise positioning under the inspection tool are crucial for optimum inspection results.

Inspection

The same requirements apply for an optical inspection as for the human eye. It is important to describe the component, define the characteristics to be tested and specify the tolerances.