Discover the people behind our success and the values that define us:

Our offer for you

Discover exciting opportunities and valuable support for your training and career! From internships and working student jobs to dual study programs - we offer you the chance to gain practical experience and expand your knowledge. Get started now and shape your future with us!

No suitable position? No problem!

Your initiative counts – simply send us an unsolicited application and convince us of your skills.

Lukas Arndt

Head of HR and Accounting

+49 (0)2871 9500-138

+49 (0)162 138 28 29

l.arndt@spaleck.biz

SPALECK Oberflächentechnik

GmbH & Co. KG

Schlavenhorst 117

D-46395 Bocholt

35 Stunden Woche

„Mehr Freizeit, weniger Stress!“ Mit einer 35-Stunden-Woche bleibt dir genug Zeit für Hobbys, Familie und spontane Ausflüge – ohne Überstundenstress.

30 Tage Urlaub

„Mehr Urlaub, mehr Power!“ Mit großzügigen 30 Tagen Urlaub kannst du dich so richtig erholen, die Welt erkunden und neue Abenteuer erleben – ohne Stress und mit viel Sonne im Herzen.

Flexible Arbeitszeiten

„Flexibel arbeiten, flexibel leben!“ Ob du früher startest, um den Nachmittag frei zu haben, oder später beginnst, um den Verkehr zu umgehen – Flexibilität steigert die Zufriedenheit und Produktivität.

Urlaubs- und Weihnachtsgeld

„Extra Geld, extra Freude!“ Urlaubs- und Weihnachtsgeld sind wie kleine Geschenke, die dir das ganze Jahr über Freude bereiten. Ob du damit deine Reisekasse aufstockst oder dir etwas Besonderes gönnst – finanzielle Extras sorgen für gute Laune und Motivation.

Ein-Schicht-Betrieb

„Eine Schicht, mehr Gelassenheit!“ Mit einer festen Schichtarbeit kannst du dich auf klare Arbeitszeiten verlassen. Kein ständiges Wechseln zwischen Früh-, Spät- und Nachtschichten – das bedeutet mehr Stabilität und weniger Stress.

Fahrradleasing

Mehr Freiheit, mehr Fitness!” Mit einem JobRad kannst du nicht nur deinen Arbeitsweg umweltfreundlich gestalten, sondern auch in deiner Freizeit entspannte Radtouren unternehmen – so förderst du deine Gesundheit.

Betriebliche Altersvorsorge

Mehr Rente, weniger Sorgen!” Unsere Betriebliche Altersvorsorge bietet dir zusätzliche finanzielle Sicherheit im Ruhestand – und das ganz ohne großen Aufwand. Durch den Arbeitgeberzuschuss wird der Aufbau der Rente unterstützt, sodass du dich entspannt zurücklehnen kannst.

Arbeitgeberfinanzierte Betriebsrente

Entsprechend deiner Betriebszugehörigkeit erhältst du zu Rentenbeginn eine einmalige Summe – ein schönes Extra für deine Zukunft!

Flache Hierarchien

„Mehr Freiheit, mehr Tempo!” Bei uns sind Entscheidungswege kürzer, die Kommunikation direkter und das Wir-Gefühl stärker. Kein langes Hin und Her – einfach loslegen!

Individuelle Weiterbildungsmöglichkeiten

„Mehr Wissen, mehr Chancen!” Durch gezielte Fortbildungen kannst du deine Fähigkeiten ausbauen, deine Beschäftigungsfähigkeit stärken und deine Karriere bei uns vorantreiben.

Eigene Lehrwerkstatt

„Mehr Selbstständigkeit, mehr individuelles Lernen!” Wir geben unseren Azubis die Möglichkeit, sich selbstständig in den Fertigungsprozess einzuarbeiten und darin von Anfang an aktiv mitzuwirken. Dabei werden sie von unseren erfahrenen Ausbildern angeleitet und können ihre Reflexionsfähigkeit sowie Selbstkontrolle üben.

35 hours week

“More free time, less stress!” With a 35-hour week, you have enough time for hobbies, family and spontaneous trips – without the stress of overtime.

30 days vacation

“More vacation, more power!” With a generous 30 days’ vacation, you can really relax, explore the world and experience new adventures – without stress and with plenty of sunshine in your heart.

Flexible working hours

“Work flexibly, live flexibly!” Whether you start earlier to have the afternoon free or start later to avoid traffic – flexibility increases satisfaction and productivity.

Vacation and Christmas bonus

“Extra money, extra joy!” Vacation and Christmas bonuses are like little gifts that bring you joy all year round. Whether you use it to top up your travel fund or treat yourself to something special – financial extras ensure a good mood and motivation.

One-shift operation

“One shift, more serenity!” With fixed shift work, you can rely on clear working hours. No constant switching between early, late and night shifts – that means more stability and less stress.

Bicycle leasing

More freedom, more fitness!” With a JobRad you can not only make your commute to work environmentally friendly, but also go on relaxed bike rides in your free time – this way you promote your health.

Company pension scheme

More pension, fewer worries!” Our company pension plan offers you additional financial security in retirement – without any major outlay. The employer subsidy helps you build up your pension, so you can sit back and relax.

Employer-financed company pension

Depending on your length of service, you will receive a lump sum at the start of your pension – a nice extra for your future!

Flat hierarchies

“More freedom, more speed!” With us, decision-making processes are shorter, communication is more direct and the sense of togetherness is stronger. No long back and forth – just get started!

Individual further training opportunities

“More knowledge, more opportunities!” Through targeted training, you can expand your skills, strengthen your employability and advance your career with us.

Own training workshop

“More independence, more individual learning!” We give our trainees the opportunity to familiarize themselves independently with the production process and actively participate in it from the very beginning. They are guided by our experienced trainers and can practise their ability to reflect and self-monitor.

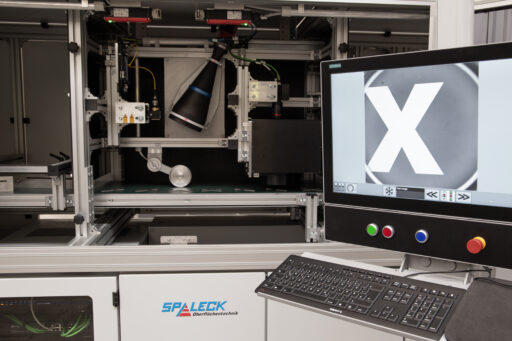

Inspection technology for maximum precision

The material handling is realized by our in-house machine construction in coordination with the requirements of the inspection technology.

Our proprietary software solution makes it possible to solve the inspection task in a customer-specific manner and includes the option of defect classification and statistical evaluation.

EMS sensors

Today, this measuring principle is used worldwide in vending machines in which coins are used for payment. Inductive testing of the coin or coin blank provides information about the material composition and/or coating of the coin/blank. The measured values of the individual object are compared with a material database and assessed as good or bad depending on the deviation from the references or the deviation defined as acceptable.

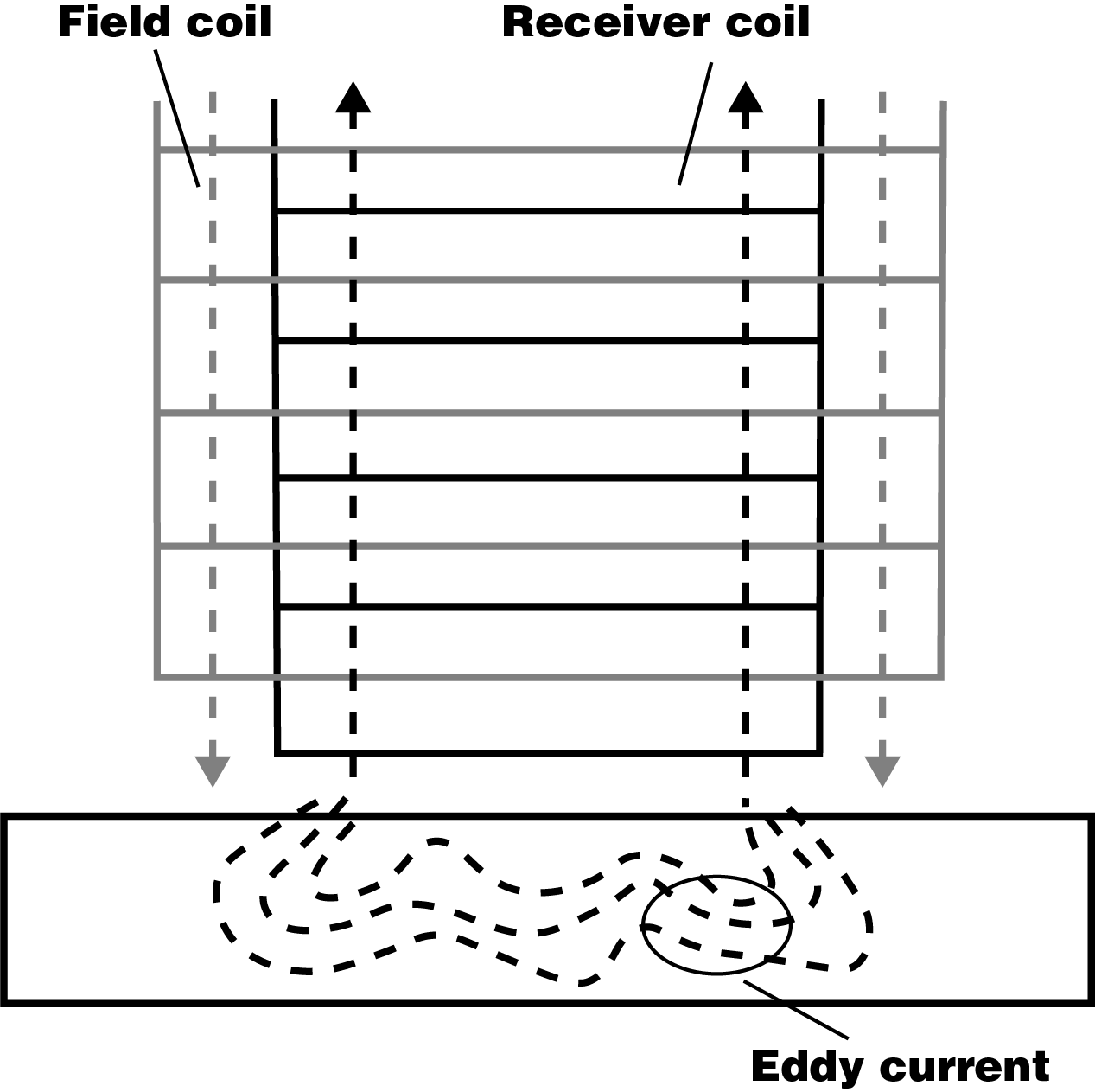

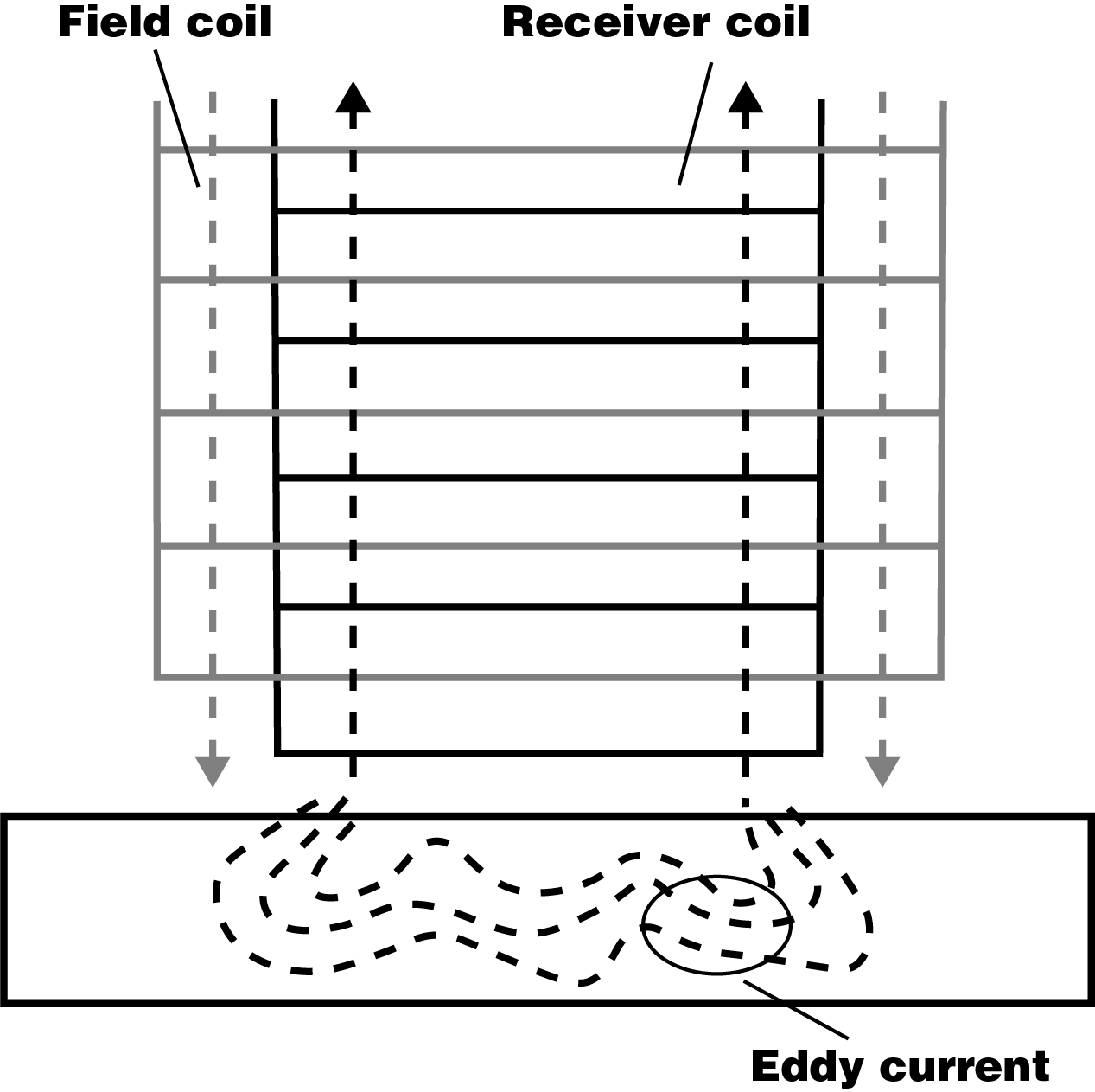

Eddy current measurement

Eddy current measurement is a non-destructive method for testing metallic surfaces. With the help of high-frequency electromagnetic interactions, different material hardnesses can be detected and analyzed both manually and automatically. This method plays a decisive role in quality assurance, as it measures the mechanical resistance of a material against the penetration of another body.

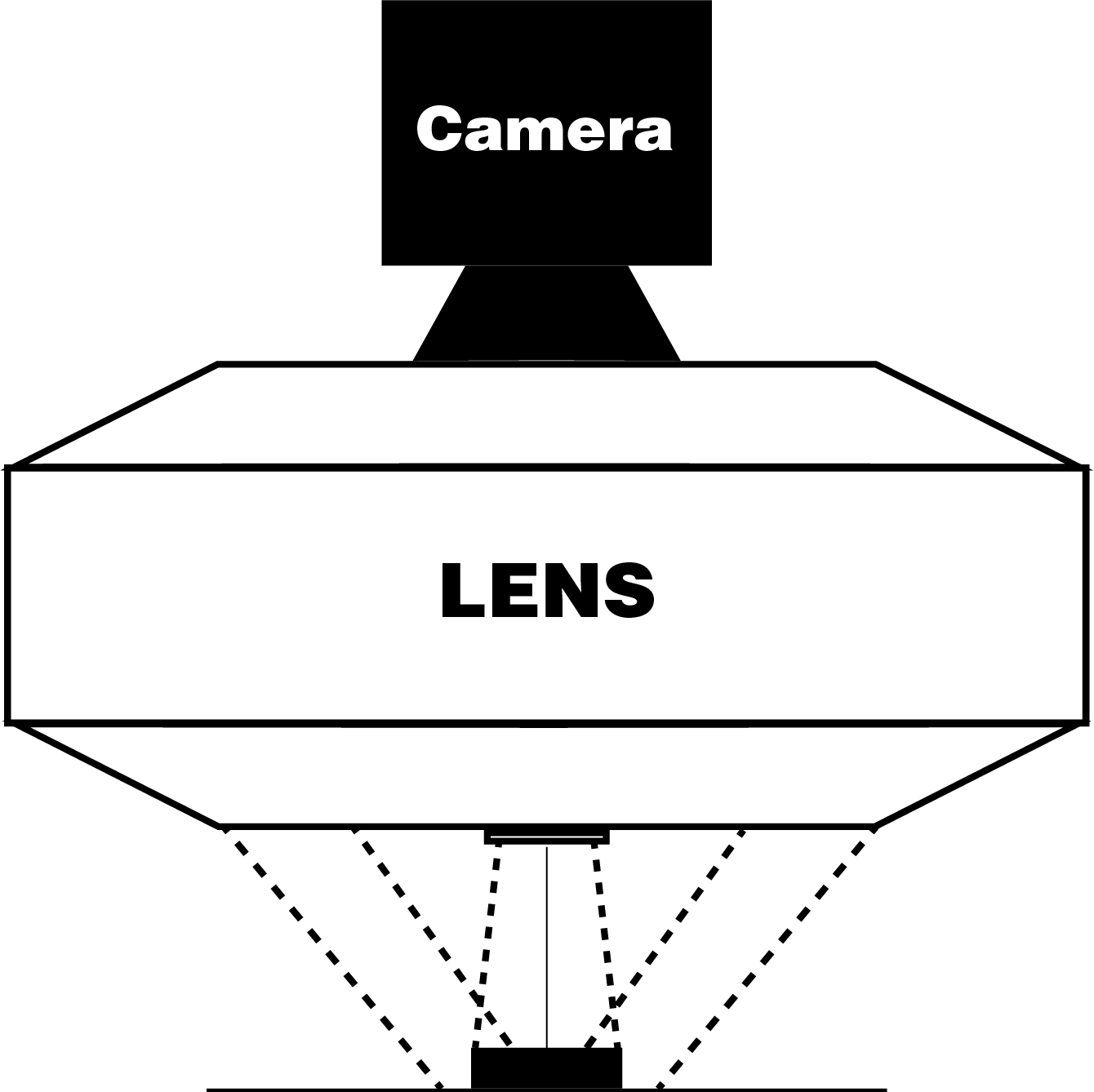

2D camera technology for edge inspection

For geometric reasons, 2D and 3D camera technology only captures the top and bottom of an object, but not the edges. A special 2D camera in combination with a ring light and a catadioptric lens is used to inspect the edge surfaces.

The following features can be checked using 2D camera technology for edge inspection:

3D camera technology

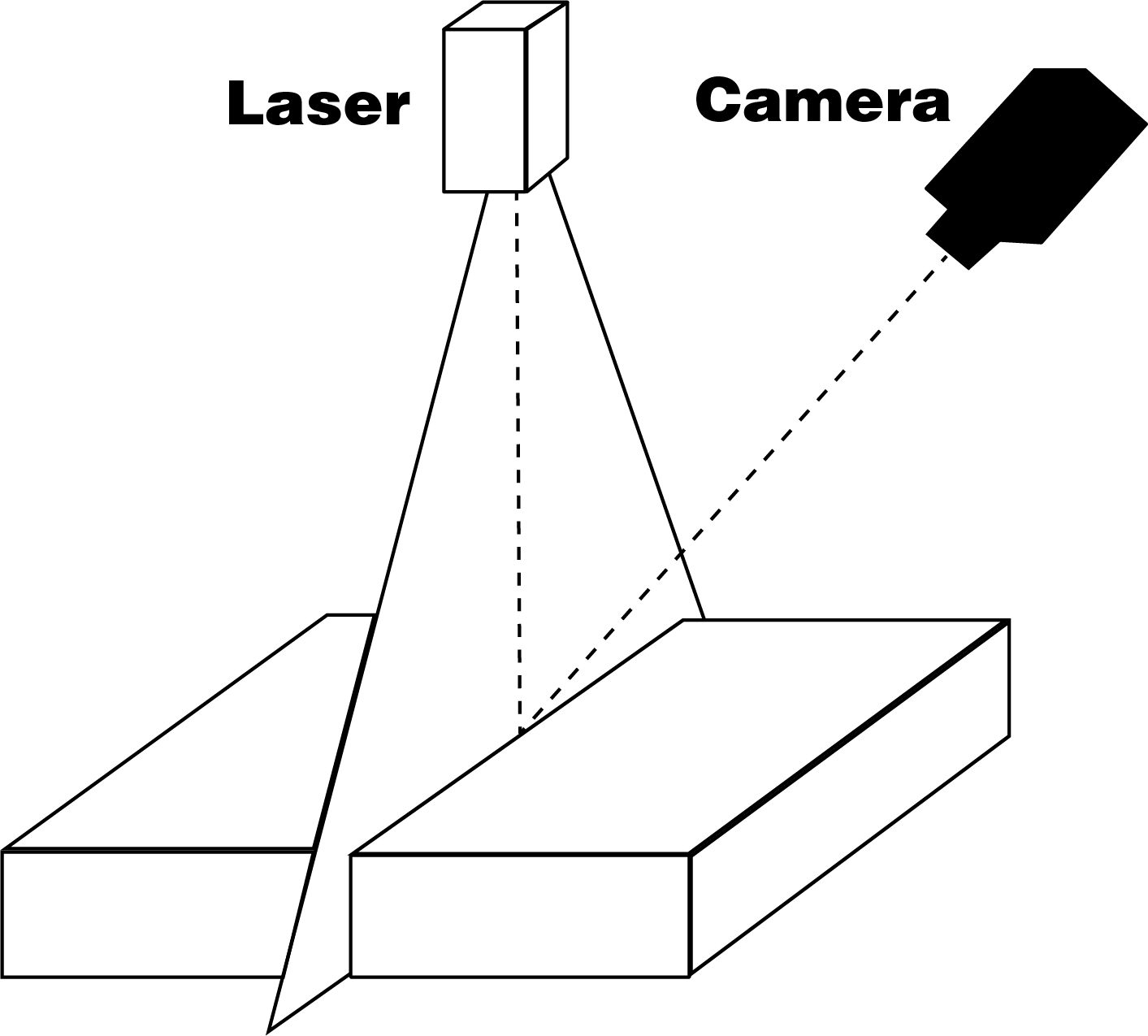

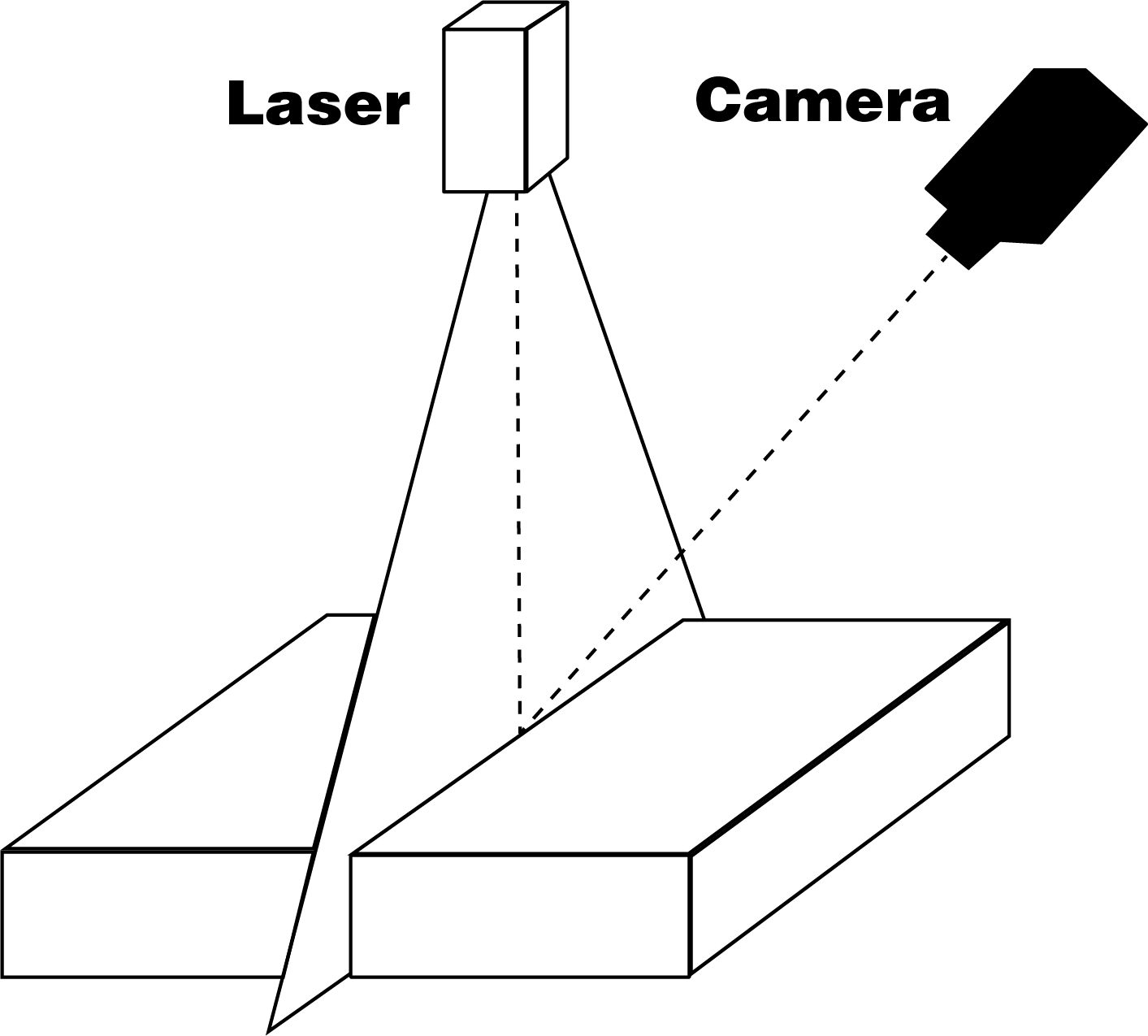

3D image capture picks up where 2D camera technology reaches its limits, particularly with regard to the depth of field of the images and the ability to recognize differences in height. To create a height profile, the component is illuminated with a line laser. The laser beam is reflected and captured by a camera. The illumination of the line laser generates many sectional images. This partial information of the component is put together by the software to form an overall object.

The following features can be checked using 3D camera technology:

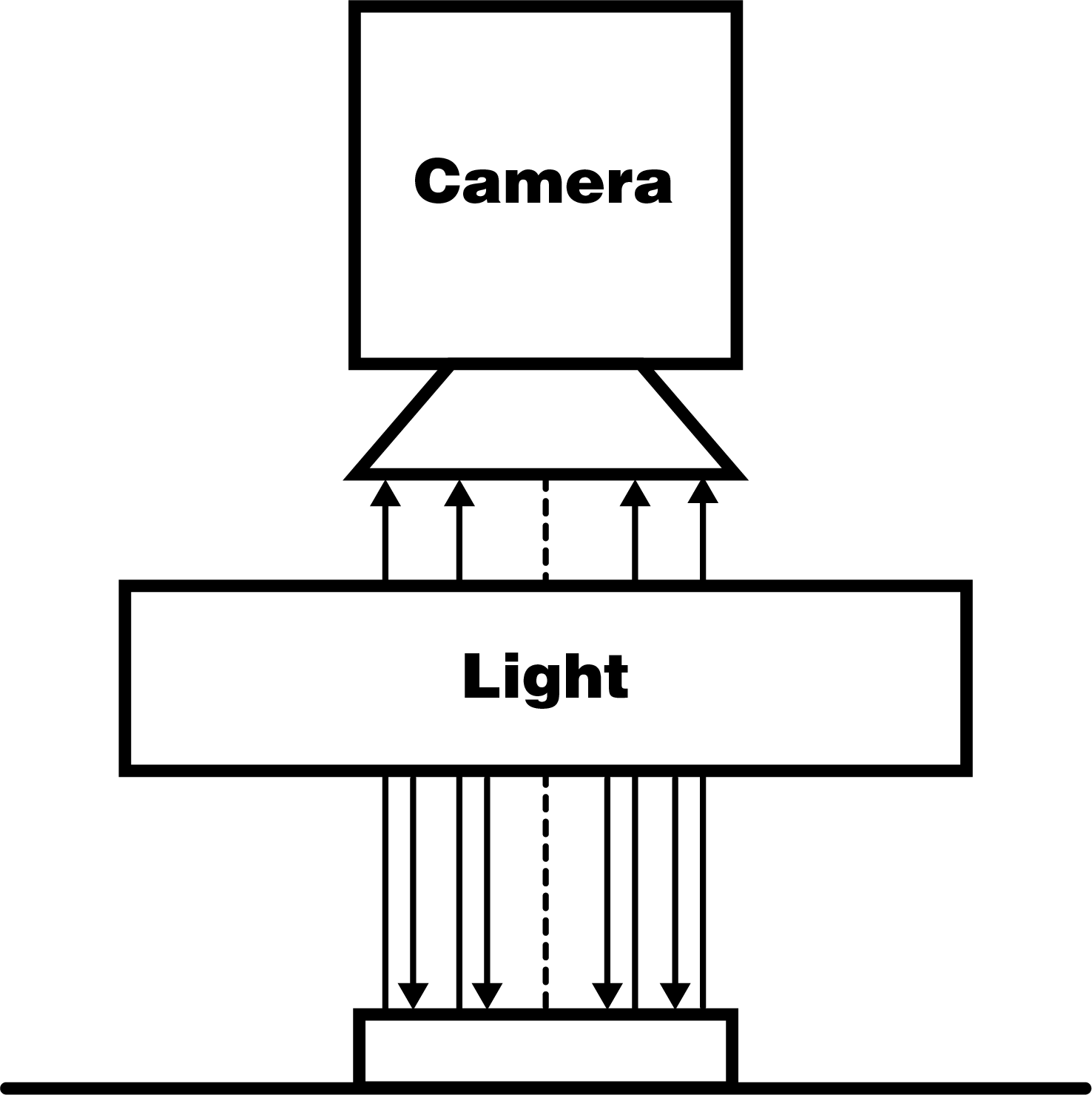

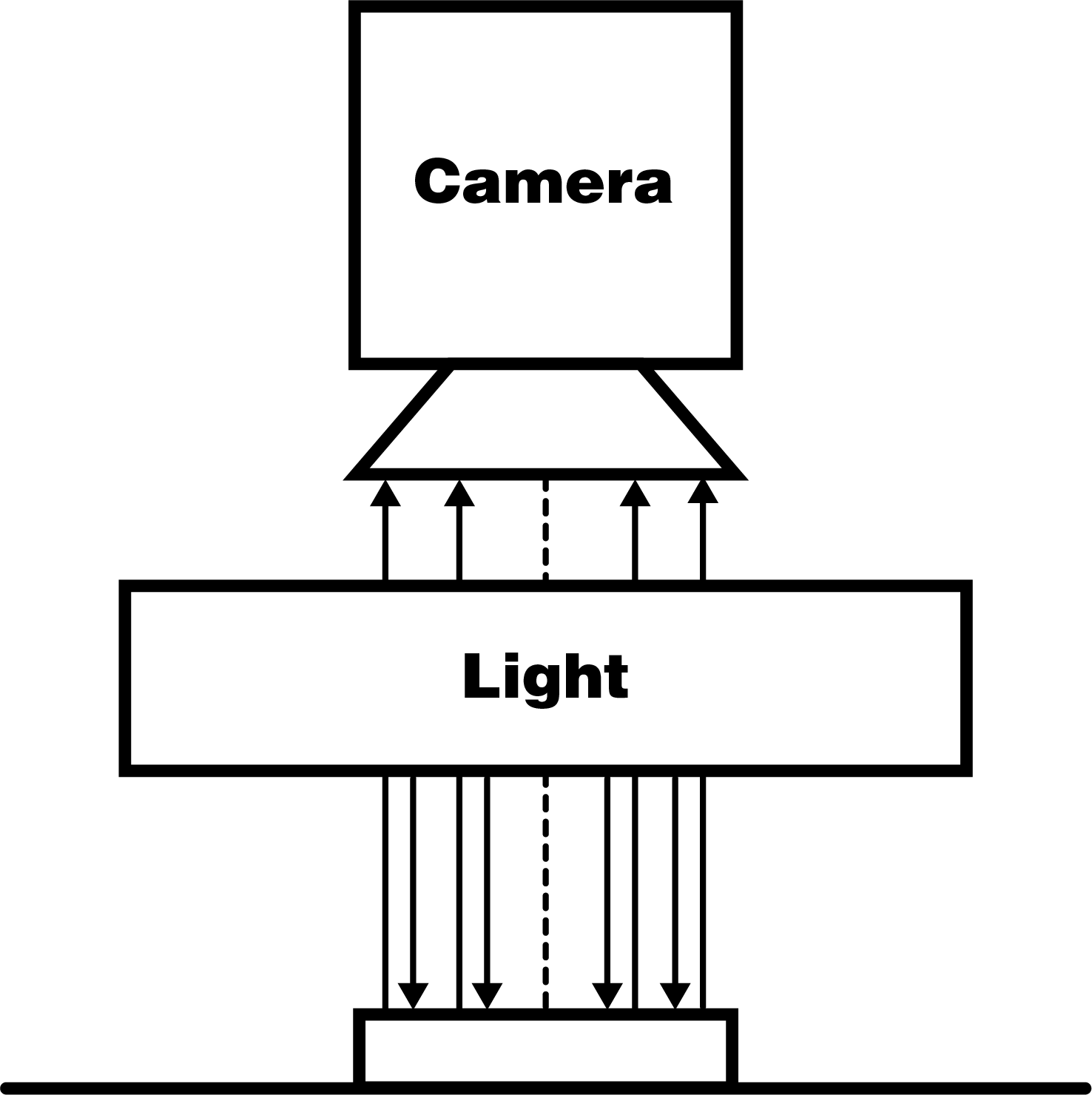

2D camera technology

2D image capture is based on the principle of the human eye – light falls on an object, is reflected and captured by the eye. In our systems, artificial lighting is used to generate light beams that are reflected by the object and captured by the camera. The choice of suitable lighting and camera depends on the application.

The following features can be checked using 2D camera technology:

Decision

The components are classified based on the set inspection parameters. The data can be stored and analyzed via an SQL database or transmitted to a higher-level system.

Image analysis

The image analysis is performed by algorithms that process the data generated by the image acquisition. These algorithms are integrated into the operating software, which is used to control the system and define and save the inspection criteria.

Image acquisition

Image acquisition includes the selection of lighting and camera technology. The type and sensitivity of the components are determined according to the previously defined test characteristics and tolerances.

Handling

The variety of components and the desired degree of automation make component handling crucial. Transport and precise positioning under the inspection tool are crucial for optimum inspection results.

Inspection

The same requirements apply for an optical inspection as for the human eye. It is important to describe the component, define the characteristics to be tested and specify the tolerances.